| Heat Transfer Film: |

|

|

|

|

|

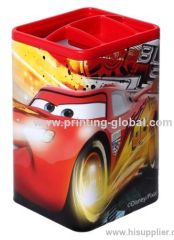

| Product Description |

|

| 1.All the printing oil is safe and poisons free with international standard |

|

| 2.Ten color patterns can be easily finished in one process |

|

| 3.Can add high values to the products for vivid patterns and live colors |

|

| 4.Strong adhesion and wear resistance after transfer printing,also can increase product value and strengthen market competitive ability |

|

| 5.Suitable for plastic(PP,ABS,AS,PET,PVC),metal,wood,bamboo,leather etc |

|

| 6.Widely used on household goods,stationery,cosmetics,electric appliance and toys etc |

|

|

|

| MOQ | 1000 square meters |

| Designer | Free |

| Packaging | 400meter/roll |

| Free cylinders | 20000square meters |

| Production time | 7days for normal,12days for laser |

| Shipping | By express,by sea,or by air |

| Maximum colors | 10 colors |

| Maximum printing width | 800mm |

| Environmental test | Yes |

| Payment condition | 100% for plate-making charge,50%deposit of the production |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Heat Transfer Film making Procedure |

| 1. Artwork | we will make an layout for you ,according to your design & size |

| ↓ |

| 2.Confirm the artwork | You Confirm the layout & we will launch your order for plate making |

| ↓ |

| 3.Plate making(cylinders) | It takes about4~7 days |

| ↓ |

| Print in big rolls →drying → cut into small rolls →quality check |

| 4.Print the film | It takes about 3 days |

| Glitter film needs 5 days more for aluminzing |

| ↓ |

| 5.Packaging | Polybag+drying agent+carton |

| ↓ |

| 6. Delivery | By sea / by air →up to you |

|

| Payment | Plate making fee & 30% film pay in advance; 70% pay before delivery. |