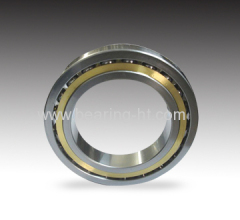

Best Price Angular Contact Ball Bearing

| Min. Order: | 500 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 500000 |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 7215C |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | KGS |

| Structure: | Angular Contact |

| Type: | Ball |

| Brand Name: | KGS |

| Model Number: | 7215C |

| Bore Size(mm): | 75 |

| Outside Diameter(mm): | 130 |

| Seals Type: | Open /ZZ /RS /RZ |

| Number of Row: | Single Row |

| Production Capacity: | 500000 |

| Packing: | Commercial packaging/Industrial packaging |

| Delivery Date: | 20-30 working days |

Product Description

Allow speed

Appropriate working conditions, the speed of the bearing is likely higher than the reference speed, but can not be higher than the value of the speed limit. In the heat to allow the development of speed, they should take full account of the special working environment. The angular contact ball bearings can directly side-by-side installation of special measures to be taken in order to achieve a single high-speed bearing.

· Heat Treatment

angular contact ball bearings after heat treatment can be no higher than 150 working temperature. 240mm in diameter than the outer ring of bearings can be no higher than 200 working temperature. If the use of nylon cage, the bearings allow the temperature to be maintained by the material plane.

Tolerance:

72B and 73BFAG single row angular contact ball bearings according to the general manufacturing tolerance (tolerance level of PN, no suffix)

· Cage

Most of angular contact bearings with glass fiber by 66 before the nylon-made cage (suffix TVP). This cage can be below 120 temperature stability of the work of the occasion. If the use of oillubricated bearings, lubricating oil additives in the cage may affect the life and a high temperature, aging of the oil will shorten the life of the cage, to strictly abide by the cycle. The use of machining brass cage of the angular contact ball bearing oil suffix MP.

· General structure

The general structure of the single row angular contact ball bearings often used in pairs, are arranged in the form of: X-type (face-to-face arrangement), O-(back-to-back arrangement) and T-type (arranged in series).

Also have the option to adjust the following types:

UA X and O-axial arrange

ment of reducing the clearance

UO X and O-type layout in zero axial clearance

Small axial clearance and zero axial clearance is the installation of non-state,

will bear paired with the installation of the bearing axial clearance to reduce, or pre increased. General Bearing structure of the order, please inform the number of individual bearings, rather than the number of bearings and bearing a number of groups.

Precision angular contact ball bearings:

Precision angular contact ball bearings are available in those dimension series-bearing series719,70,72-with an contact angle of 15 degree (designation suffix C), 25 degree (designation suffix AC) or 40 degree (designation suffix B). Beatings with the larger contact angle are recommended for applications where high axial stiffness and high axial load carrying capacity are required.

Application:

Single-row angular contact ball bearings: machine tool spindles, high-frequency motors, gas turbines, centrifuges, small automobile front wheels, differential pinion shafts.

Double-row angular contact ball bearings: oil pumps, Roots blowers, air compressors, various types of transmissions, fuel injection pumps, printing machinery.

| Angular Contact Ball Bearing | |||||

| Model | Old model | Dimesion(mm) | Weight | ||

| d | D | T | |||

| 7000AC | 46100 | 10 | 26 | 8 | 0.02 |

| 7001AC | 46101 | 12 | 28 | 8 | 0.02 |

| 7002AC | 46102 | 15 | 32 | 8 | 0.03 |

| 7003AC | 46103 | 17 | 35 | 10 | 0.03 |

| 7004AC | 46104 | 20 | 42 | 10 | 0.07 |

| 7005AC | 46105 | 25 | 47 | 12 | 0.08 |

| 7006AC | 46106 | 30 | 55 | 13 | 0.12 |

| 7007AC | 46107 | 35 | 62 | 14 | 0.14 |

| 7008AC | 46108 | 40 | 68 | 15 | 0.21 |

| 7009AC | 46109 | 45 | 75 | 16 | 0.24 |

| 7010AC | 46110 | 50 | 80 | 16 | 0.26 |

| 7011AC | 46111 | 55 | 90 | 18 | 0.38 |

| 7012AC | 46112 | 60 | 95 | 18 | 0.45 |

| 7013AC | 46113 | 65 | 100 | 18 | 0.5 |

| 7014AC | 46114 | 70 | 110 | 20 | 0.59 |

| 7015AC | 46115 | 75 | 115 | 20 | 0.75 |

| 7016AC | 46116 | 80 | 125 | 22 | 0.9 |

| 7016ACM | 46116H | 80 | 125 | 22 | 0.9 |

| 7017AC | 46117 | 85 | 130 | 22 | 0.95 |

| 7017ACM | 46117H | 85 | 130 | 22 | 0.95 |

| 7018AC | 46118 | 90 | 140 | 24 | 0.96 |

| 7018ACM | 46118H | 90 | 140 | 24 | 0.96 |

| 7019AC | 46119 | 95 | 145 | 24 | 1.2 |

| 7019ACM | 46119H | 95 | 145 | 24 | 1.2 |

| 7020AC | 46120 | 100 | 150 | 24 | 1.25 |

| 7020ACM | 46120H | 100 | 150 | 24 | 1.25 |

| 7021ACM | 46121H | 105 | 160 | 26 | 1.61 |

| 7022ACM | 46122H | 110 | 170 | 28 | 2.44 |

| 7024ACM | 46124H | 120 | 180 | 28 | 2.62 |

| 7026ACM | 46126H | 130 | 200 | 33 | 3.912 |

| 7028ACM | 46128H | 140 | 210 | 33 | 4.2 |

| 7030ACM | 46130H | 150 | 225 | 35 | 5 |

| 7032ACM | 46132H | 160 | 240 | 38 | 5.02 |

| 7034ACM | 46134H | 170 | 260 | 42 | 8.3 |

| 7038ACM | 46138H | 190 | 290 | 46 | 11.2 |

| 7040ACM | 46140H | 200 | 310 | 51 | 14.3 |

| 7044ACM | 46144H | 220 | 340 | 56 | 18.5 |

| 7048ACM | 46148H | 240 | 360 | 56 | 19.7 |

| 7200AC | 46200 | 10 | 30 | 9 | 0.031 |

| 7201AC | 46201 | 12 | 32 | 10 | 0.036 |

| 7202AC | 46202 | 15 | 35 | 11 | 0.044 |

| 7203AC | 46203 | 17 | 40 | 12 | 0.08 |

| 7204AC | 46204 | 20 | 47 | 14 | 0.102 |

| 7205AC | 46205 | 25 | 52 | 15 | 0.12 |

| 7206AC | 46206 | 30 | 62 | 16 | 0.2 |

| 7207AC | 46207 | 35 | 72 | 17 | 0.3 |

| 7208AC | 46208 | 40 | 80 | 18 | 0.37 |

| 7209AC | 46209 | 45 | 85 | 19 | 0.41 |

| 7210AC | 46210 | 50 | 90 | 20 | 0.45 |

| 7210ACM | 46210H | 50 | 90 | 20 | 0.45 |

| 7211AC | 46211 | 55 | 100 | 21 | 0.6 |

| 7211ACM | 46211H | 55 | 100 | 21 | 0.6 |

| 7212AC | 46212 | 60 | 110 | 22 | 0.81 |

| 7212ACM | 46212H | 60 | 110 | 22 | 0.81 |

| 7213AC | 46213 | 65 | 120 | 23 | 1.01 |

| 7213ACM | 46213H | 65 | 120 | 23 | 1.01 |

| 7214AC | 46214 | 70 | 125 | 24 | 1.08 |

| 7214ACM | 46214H | 70 | 125 | 24 | 1.08 |

| 7215AC | 46215 | 75 | 130 | 25 | 1.23 |

| 7215ACM | 46215H | 75 | 130 | 25 | 1.23 |

| 7216AC | 46216 | 80 | 140 | 26 | 1.48 |

| 7216ACM | 46216H | 80 | 140 | 26 | 1.48 |

| 7217AC | 46217 | 85 | 150 | 28 | 1.88 |

| 7217ACM | 46217H | 85 | 150 | 28 | 1.88 |

| 7218AC | 46218 | 90 | 160 | 30 | 2.18 |

| 7218ACM | 46218H | 90 | 160 | 30 | 2.18 |

| 7219ACM | 46219H | 95 | 170 | 32 | 2.72 |

| 7220ACM | 46220H | 100 | 180 | 34 | 3.28 |

| 7221ACM | 46221H | 105 | 190 | 36 | 3.95 |

| 7222ACM | 46222H | 110 | 200 | 38 | 4.81 |

| 7224ACM | 46224H | 120 | 215 | 40 | 5.6 |

| 7226ACM | 46226H | 130 | 230 | 40 | 7.3 |

| 7228ACM | 46228H | 140 | 250 | 42 | 7.76 |

| 7230ACM | 46230H | 150 | 270 | 45 | 10.5 |

| 7232ACM | 46232H | 160 | 290 | 48 | 14.5 |

| 7234ACM | 46234H | 170 | 310 | 52 | 16.5 |

| 7236ACM | 46236H | 180 | 320 | 52 | 18.1 |

| 7238ACM | 46238H | 190 | 340 | 55 | 18.8 |

| 7240ACM | 46240H | 200 | 360 | 58 | 24 |

| 7244ACM | 46244H | 220 | 400 | 65 | 38.5 |

| 7301AC | 46301 | 12 | 37 | 12 | 0.065 |

| 7302AC | 46302 | 15 | 42 | 13 | 0.094 |

| 7303AC | 46303 | 17 | 47 | 14 | 0.12 |

| 7304AC | 46304 | 20 | 52 | 15 | 0.146 |

| 7305AC | 46305 | 25 | 62 | 17 | 0.23 |

| 7306AC | 46306 | 30 | 72 | 19 | 0.35 |

| 7307AC | 46307 | 35 | 80 | 21 | 0.47 |

| 7307ACM | 46307H | 35 | 80 | 21 | 0.47 |

| 7308AC | 46308 | 40 | 90 | 23 | 0.69 |

| 7308ACM | 46308H | 40 | 90 | 23 | 0.69 |

| 7309AC | 46309 | 45 | 100 | 25 | 0.89 |

| 7309ACM | 46309H | 45 | 100 | 25 | 0.89 |

| 7310AC | 46310 | 50 | 110 | 27 | 1.08 |

| 7310ACM | 46310H | 50 | 110 | 27 | 1.08 |

| 7311AC | 46311 | 55 | 120 | 29 | 1.39 |

| 7311ACM | 46311H | 55 | 120 | 29 | 1.39 |

| 7312AC | 46312 | 60 | 130 | 31 | 1.71 |

| 7312ACM | 46312H | 60 | 130 | 31 | 1.71 |

| 7313AC | 46313 | 65 | 140 | 33 | 2.09 |

| 7313ACM | 46313H | 65 | 140 | 33 | 2.09 |

| 7314AC | 46314 | 70 | 150 | 35 | 2.67 |

| 7314ACM | 46314H | 70 | 150 | 35 | 2.67 |

| 7315AC | 46315 | 75 | 160 | 37 | 3.1 |

| 7315ACM | 46315H | 75 | 160 | 37 | 3.1 |

| 7316AC | 46316 | 80 | 170 | 39 | 3.97 |

| 7316ACM | 46316H | 80 | 170 | 39 | 3.97 |

| 7317AC | 46317 | 85 | 180 | 41 | 4.84 |

| 7317ACM | 46317H | 85 | 180 | 41 | 4.84 |

| 7318AC | 46318 | 90 | 190 | 43 | 5 |

| 7318ACM | 46318H | 90 | 190 | 43 | 5 |

| 7319ACM | 46319H | 95 | 200 | 45 | 5.7 |

| 7320ACM | 46320H | 100 | 215 | 47 | 7.53 |

| 7321ACM | 46321H | 105 | 225 | 49 | 8.62 |

| 7322ACM | 46322H | 110 | 240 | 50 | 11.3 |

| 7324ACM | 46324H | 120 | 260 | 55 | 15.6 |

| 7326ACM | 46326H | 130 | 280 | 58 | 17.3 |

| 7328ACM | 46328H | 140 | 300 | 62 | 22.4 |

| 7328BM | 66328H | 140 | 300 | 62 | 22.4 |

| 7330ACM | 46330H | 150 | 320 | 65 | 26 |

| 7332BM | 66332H | 160 | 340 | 68 | 30.2 |

| 7334BM | 66334H | 170 | 360 | 72 | 35.6 |

| 7336BM | 66336H | 180 | 380 | 75 | 41.3 |

| 7338BM | 66338H | 190 | 400 | 78 | 45.5 |

| 7344BM | 66344H | 220 | 460 | 88 | 70 |

| 7406AC | 46406 | 30 | 90 | 23 | 0.77 |

| 7406ACM | 46406H | 30 | 90 | 23 | 0.77 |

| 7407AC | 46407 | 35 | 100 | 25 | 0.95 |

| 7407ACM | 46407H | 35 | 100 | 25 | 0.95 |

| 7408AC | 46408 | 40 | 110 | 27 | 1.41 |

| 7408ACM | 46408H | 40 | 110 | 27 | 1.41 |

| 7409ACM | 46409H | 45 | 120 | 29 | 1.77 |

| 7410ACM | 46410H | 50 | 130 | 31 | 2.1 |

| 7412ACM | 46412H | 60 | 150 | 35 | 2.8 |

| 7413ACM | 46413H | 65 | 170 | 40 | 3.85 |

| 7414ACM | 46414H | 70 | 180 | 42 | 5.9 |

| 7416ACM | 46416H | 80 | 200 | 48 | 7 |

| 7418ACM | 46418H | 90 | 225 | 54 | 10 |