Roller T Shirt Heat Transfer Equipment Air Compressor 2 in 1 Capability

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FAS,DDP,CIP,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, T/T, Money Gram |

| Supply Ability: | 100 Sets Per Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Heat Press Machine, Heat Transfer Machine, Dye Sublimation Printers, Eco-solvent Printer. |

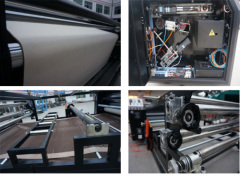

Product Detail

| Model No.: | AP-26B |

|---|---|

| Means of Transport: | Ocean, Land |

| Plate: | Flatbed Printer |

| Type: | Heat Transfer |

| Color & Page: | Multicolor |

| Usage: | Paper Printer |

| Brand Name: | Asiaprint |

| Type: | Roller heat transfer machine |

| Blanket: | Dupont |

| Feeding Method: | top feeding |

| Transfer Mode: | Roll To Roll / Cut-piece |

| Fed-in Media: | Transfer Paper, Fabric, Protective Paper |

| Power Supply: | Connection Required By A Specialist |

| Transfer Speed: | 3~5 M/Min |

| Door To Door Service: | Offered |

| Heating Media: | Electric With Thermal Oil |

| Mob: | +86-13728059112 |

| Production Capacity: | 100 Sets Per Month |

| Packing: | Packed in Rigid Standard Export Wooden Case |

| Delivery Date: | 15 working days after received your payment |

Product Description

Quick Reviews

♦ Roll Width: 1800 mm

♦ Drum Diameter : 600 mm

♦ Transfer speed: 3M / Min

♦ Roll Drum Oil Volume : 100%

♦ Safety equipment: Explosion-proof system

♦ Offers the versatility of roll-to-roll, cut-sheet, and/or cut-piece feeding.

Technical Data

Model | AP-26B |

Heating Media | oil |

Maximum Media Width | 1800 mm |

Diameter of Drum | 600 mm |

Transfer Speed | 3M / Min |

Temperature Range | 0-399 ℃ |

Time Range | 0-999 S |

Function of Roll-to-Roll | yes |

Function of Cut Sheet | yes |

Working Table | including |

Fed-in media | Transfer paper,fabric,protective paper |

Voltage / Heating Power | 220 volts 3-phase or 380 volts 3-phase. |

Machine Size(L*W*H) | 2670*1570*1700mm |

Packing Dimension(L*W*H) | 2840*1680*1900mm |

Weight | 2100 KG |

Other Available sizes | 1700mm 1900mm 2000mm (custom sizes by special order!) |

Scope of Delivery | Roller heat transfer machine, Power cable without plug, some spare parts for free |

Highlights

♦ It guarantees reduction of production costs, while increasing productivity, as well as multiple

working systems.

♦ Perfect uniformity of temperature.Coated in chrome steel with armored resistances immersed in oil,

ensuring optimal temperature uniformity.

♦ Digital speed controller that allows you to better control your production.

♦ Maximum usage of paper and sublimation ink within the entire application area.

♦ Separate immediately after printing,which improves quality of colors and detail sharpness,

without any shadows or stains.

♦ No specialized labor required, i.e., the quality of the thermal transfer lays on the machine rather

than on the operator skills when compared to conventional heat presses.

♦ Easy Operation and Control System with Digital Temperature Readings

♦ Includes a Working Table for Easy Cut Sheet Workflow Setup and Production

♦ Heighten Oil tank, sealed oil drum, which ensure 100% uniformity of temperature.

♦ Conveyor belt for material out the back of the device and tensioning system with active rocker

providing work with tissue elasticity.

Fundamental Elements

♦ Eco-friendly process (no solvents whatever, and no use of water)

♦ Ease and versatility of use

♦ Quick and simple change of pattern/image

Why Choose us

♦ Reliable quality and good reputation

More than 30sets roller heat transfer machines selling overseas and gain many satisfied customers world-wide, patented solutions and an extensive experience acquired in numerous fields of application: this, in short, is what the company offers to all its customers the world over, be they multinational corporations or small enterprises.

♦ OEM Service & ODM Service Offered Whatever the customer's aim or requirement we can provide the right solution in record time: in addition to our standard machines, we are asked increasingly to come up with custom or prototype solutions, sharing the know-how needed in order to deliver the agreed objective, and always with maximum confidentiality.

♦ Best Customer Service

Though some of customers just pay once for purchasing equipment and perfect service, use and maintain always keep accompanying from beginning to end.All function can be understood and used easily without any professional knowledge at all. The preventive maintenance during warranty. Our professional engineers will remote assistance for confirming problems, go a step further to offer door-to-door service.

Warmly welcome to be one of our distributor!

Ideal Application

Ideal for transferring high quality images onto polyester fabrics, the machine is able to image roll-to-roll and cut sheet applications such as dye sub banners, soft signage, displays, cut and sew dye sub,sportswear, ladies/mens/fitness garments and more. It allows for applying prints to every type of textile goods, including large sizes like towels, flags, etc