container homes 40ft HQ luxury prefab modular modern villa

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Description

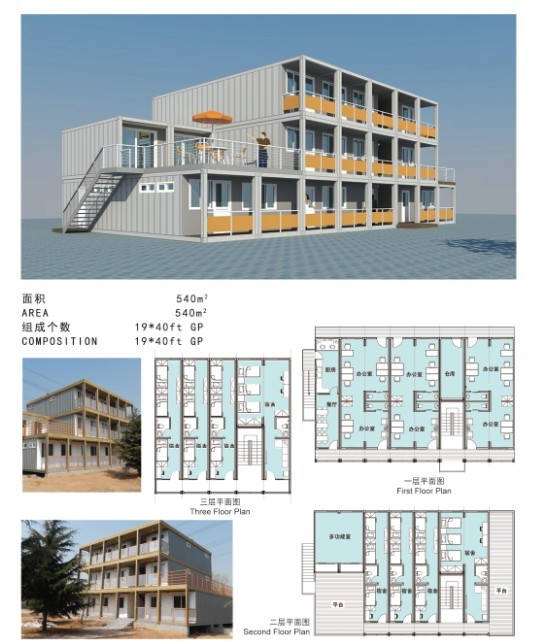

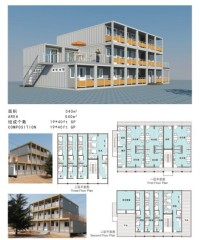

Modular Container House

1. The benefits of Container House

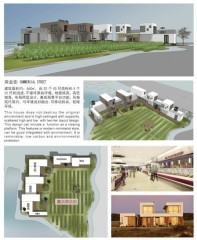

Perfect for modular/ prefab site offices, cabins, warehouse, villa, shop, hotel, camp, office.

Efficient, low cost designs that can be customized for end user requirements.

Easy for low skilled workers to assemble.

The light steel frame structure is strong and reliable.

Many modular units can be stacked and linked together to create more space.

Neat inside: plumbing and wires are hidden into the sandwich panel.

2. Container House Description

Corner fitting | Made of Q345B seamless welded steel tube, less solder sides, more firm; polishment makes the surface more smooth, and make it more firm; CNC drilling holes, more accurate and perfect; first galvanized, then painted with anti-corrosive paints. |

Steel pillar | Made of Q345B seamless welded steel tube, less solder sides, CNC bending; first galvanized, then painted with anti-corrosive paints. |

Beam | Made of Q345B seamless welded steel tube, less solder sides, CNC bending; first galvanized, then painted with anti-corrosive paints. |

Frame soldering | Sealed soldering makes the frame more firm |

Painting workshop | The FC paints with good adhesive force, makes the container house bright and fresh. |

Installed the wires& wipes in advance | The inner space will be more beautiful. |

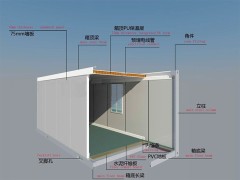

The roof | Integrated with PU (steel parts+colored steel sheet on both sides+PU foaming), the water proof is well solved. Bearing capacity is 0.5t. |

EPS wall panel | Using the stainless steel to protect it from rusting |

Windows& doors | Fitted in the wall panel, easy to adjust |

Switch | Installed the wires and slots in advance which make the inner space more safe and artistic |

Laminate floor | Laminate floor make the room comfortable and artistic |

PVC floor | Well water proof |

PVC belt course | Make the floor more artistic |

Installation of the bottom's drainage system | Its installation is according to the place of the toilet |

Semi-finished product& accessories& supporting facilities | |

Introduction of the bottom | frame made of Q235 steel board, seamless bended, seamless welded, surface galvanized. Painted with anti-corrosive paints, laying materials: laminate board, PVC board, blockboard, cement fiber board etc. |

Bottom serial | 1. Standard laminate floor |

Introduction of the wall system | consists of 0.42mm colored steel sheets on both sides or one 0.42 colored sheet and one 0.42mm stainless sheet, integrated with PU\EPS\ROCK WOOL etc. The size of the wall is 2310mm*1158mm. The thickness of the external wall is 75mm, and the internal wall is 50mm. The density of the EPS is 12kg\m³, the density of the rock wool is 100kg\m³. And the color of the wall is as per the clients' demands. |

Wall system series | 1. Standard wood pattern wall panel |

Accessories | Decoration strip, skirting line, inner corner, inner corner pedestal, corner parts, plastic seaming rib, wall panel fixer, socket, switch(AM, AU, BR, Taiwan standard), day light lamp support, steel security door, security door lock, 1exhaust fan, stairway bracket connection, Laminate floor |