WDW-100 Electronic Universal Testing Machine + Medical Bone Surgical Implant Test+ Pull Out Test Of Bone Screw

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Usage: | Universal Testing Machine |

| Power: | Electronic |

| Brand Name: | Chenda |

| max. test force: | 100KN |

| Test force testing range: | 0.4%-100%FS |

| Control system: | servo drive controller |

| Test speed: | 0.005-500mm/min |

| Tensile test space: | 550mm |

| Compression test space: | 800mm |

| Compression Diameter: | 100mm |

| Weight: | 550kg |

| Power Supply: | 220volts, 3 phase, 60 hertz |

| Production Capacity: | 300 |

| Packing: | wodden case |

| Delivery Date: | 3-5 days after received the payment |

Product Description

WDW-100 Static Universal Testing Machine+For Medical Bone Surgical Implant

Brief Information

WDW-100 Static universal testing machine for medical bone surgical implant is designed and manufactured according to ASTM, ISO,DIN etc standards. It is computer-controlled precision testing machine, Suitable for all kinds of surgical implants such as bone plates, bone screws, spinal implant assembly drawing . Can do all kinds of Mechanical property test such as compression, bending, pull-out strength test and so on .

According To The Standard:

1.GB/T16491-2008 < < Electronic Universal Testing Machine > >,

2.GB/T228.1-2010

3.ASTM F382-99 RESISTENCIA A LA FATIGA FLEXION EN 4 PUNTOS

4.ASTM F543,

5.ASTM F1717

Feature:

1> Complete computer controlled: the whole measuring and controlling system adopts

specific PC control card used for testing machines, realizing the data zero and plus adjustment, which has very high reliability.

2>Supporting multi-transducers. Realizing the database management of the test data which are stored according to the standard format; facilitating other software to analyze and transfer.

3> Perfect programming by auto program control, every control mode can smoothly shift to another one. Fulfilling the test requirement of all kinds of materials with every test standard home and abroad.

4>Control software has the the auto-adjusting function of test hardness, which assures that the system works with every kind of specimen hardness.

5>Perfect graphic function realizing the arbitrarily magnifying, decreasing, equaling, adding, indicative display and print of all kinds of test curves, the test point searching as well as the simultaneous display and print of several kinds of test curves. Data processing supposes self-disposing and input disposing of graphic human computer interaction, which facilitates the check and contrast of the test result.

6>The user can self-define the output of the test report, which makes the report format have high flexibility.

7>Modularization design facilitated the software upgrading, function spreading as well as the second development.

Test function introduction:

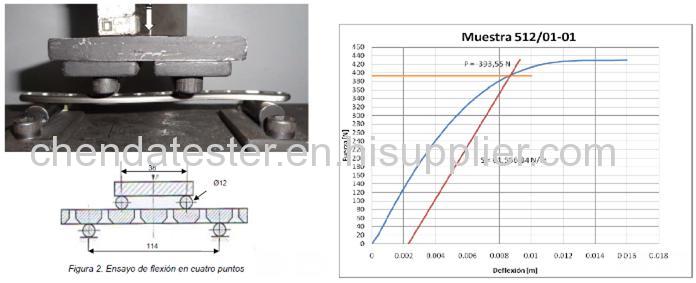

1.Four point bending test of bone plate

Bending Roller Diameter ¢12mm Span:36mm

Supporting spacing :114mm

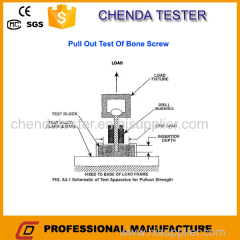

2.Pull out test of the bone screw

Please inform me the shape and size of the Screw so that we can confirm the size and shape of the device as shown in the picture on the right.

3.Tensile and compression tests for spinal implants:

Please inform me the size of the connection dimension between the Polyethylene and Fixtures

4.Metal Tensile Testing

5.Test As follows

Technical specification:

Mode | WDW-100 |

max. test force | 100KN |

Test force testing range | 0.4%-100%FS |

Testing machine accuracy grade | 1 |

Accuracy of test force | Better than indication value ±1%(0.5%) |

Crosshead displacement resolution | 0.001mm |

Large deformation measuring range | 2%-100%FS |

Large deformation resolution | 1/200000 |

Control system | servo drive controller |

Test speed | 0.005-500mm/min |

Auto-stop function | 1.maximun capacity overload protection 2.leakage current protection |

Adjust speed range | 0.005-500mm/min |

Tensile test space | 550mm |

Compression test space | 800mm |

Tensile Clamping (Flat jaw )mm | 0-7,7-14,14-20 |

Tensile Clamping (Round jaw)mm | 4-9,9-14,14-20 |

Compression Diameter | φ100mm |

Bending Roller Diameter mm | 12 |

Host type | door structure |

Host dimension | 840mm x 600mm x 1750mm |

Weight | 500kg |

Power Supply | 220volts, 3 phase, 60 hertz |

Working environment | Room temperature 45 humidity 20%-80% |

Standard delivery:

NO. |

Brand Name | ||

1 | Test host | 1 | |

2 | AC servo motor | 1 | |

3 | Speed governor | 1 | |

4 | Load cell | 1 | |

5 | Precision ball screw | 2 | |

6 | Deceleration system | 1 | |

7 | Computer control system | 1 | |

8 | Optical encoder | 1 | |

9 | Computer | Lenovo | 1 |

10 | Printer | Hp color ink jet printer | 1 |

11 | PCI Card | 1 | |

12 | Windows system software | 1 | |

13 | Specific tools | 1 | |

14 | Tensile accessory | Flat jaw0-7,7-14,14-20 Round jaw4-9,9-14,14-20 | 1 |

15 | Compression accessory | φ100mm | 1 |

16 | Bending accessory | 1 | |

17 | Technical information | 1 |