WAW-1000D Hydraulic Universal Testing Machine +Steel Tensile Strength Testing Machine +Universal Tensile Testing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 300 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Usage: | Universal Testing Machine |

| Power: | Hydraulic |

| Brand Name: | Chenda |

| Max test force kN: | 1000 |

| relative error of test force: | ±1% |

| The width of flat specimen mm: | 80 |

| Max. Tensile test space mm: | 620 |

| Max. Compression test space mm: | 550 |

| Control cabinet Dimensions mm: | 1200 620 850 |

| Column clearance (mm): | 580 |

| Production Capacity: | 300 |

| Packing: | wooden box |

| Delivery Date: | 3-5 days |

Product Description

Brief Introduction:

WAW -1000D Series Computer Control Servo Hydraulic Universal Testing Machine, compared with a ball screw type electric mechanical UTM, is adopting oil hydraulic power to push the piston in the oil cylinder to provide loading force. Therefore it is very suitable for making test to different metal and nonmetal materials under high toughness and hardness against extreme big loading force. By using oil pressure transducer and photoelectric encoder, the computer is timely collecting the testing parameter like loading force, stroke etc. The servo system will provide on line close loop control and constant parameters control. The test software is able to create customized testing methods and setup testing report in only a few steps. WAW series is widely used in different inspection department, engineering area, universities and institutes.

Standards:

1) ISO6892: DIN EN 10002-1, JIS Z2241, BS-18, ASTM E8: Metallic Material-Tensile Testing at Ambient Temperature.

2) ASTM A730: Standard Test Methods and Definitions for Mechanical Testing of Steel Products

3) ASTM E4: Standard Practices for Force Verification of Testing Machines

4) EN 10002-4: Tensile Testing Of Metallic Materials - Verification of Extensometers Used In Uniaxial Testing

5) ISO75000-1: Verification of Tension/Compression Testing Machines

Load Frame:

The oil cylinder is at the bottom of the load frame. Tension space is at the upside and compression & bending spaces are between lower crosshead and working table. It is adopting oil hydraulic power to push the piston in the oil cylinder to provide loading force. The lower crosshead is driven by motor through decelerator, chain transmission device and screw pair to realize the adjustment of testing space.

Measuring System:

The machine adopts oil pressure transducer to measure load and use photoelectric encoder to measure the displacement. The loading force display on computer

Control System

1>By using oil pressure transducer.

2>Full computer controlled of testing process.

3>Adopt oil-hydraulic automatic clamps which can be operated from separate control box

4>Wedge tension jaw processed by advanced technology; increase the stiffness of crosshead under high load and high intensity test.

Max Test Software

1>Powerful multifunctional control software will provide more testing methods to meet ASTM, ISO and other testing standards.

2>Computer software system is highly integrated, stable performance, easy to adjust and so on. In real-time experimental data can be collected, the experimental realization of real-time dynamic display characteristic curves, test data files can be used with Access database

3>Protection function: This machine has two kinds of software and mechanical limit conservation, exceeds the maximum load can be automatically shut down the ratio of dynamic setting; with the over-current, over voltage, overload and other protection functions..

4>Batch test can achieve the curves at different levels show.

5>The software enables the user to customize the speed settings to adjust the speed of the computer.

6>The results reproduce features

7>According to the user can choose load ~ time , load ~ displacement ,displacement ~ time curve to carry out testing and data display, storage, analysis and printing.

Report guide will create your testing report in only three steps.

8>Power Interface: Force-channel interface and test software according to user needs with a variety of sensors, and can be calibrated, modify parameters and the normal test.

9>Data sampling frequency: You can choose according to the user test requirements of high-speed sampling frequency.

Technical specifications:

Specification | WAW-1000D |

Max. capacity (KN) | 1000 |

Relative error of reading | ≤±1% |

Clamping method | Hydraulic clamping |

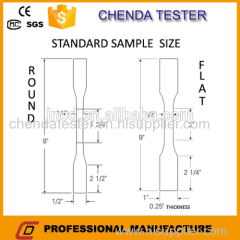

Round specimen clamping range(mm): | Φ13~Φ26 Φ26~Φ40 Φ40~Φ60 |

Flat specimen clamping thickness(mm): | 0-40 |

Flat specimen clamping width(mm): | 110 |

Max. tension test space (mm) | 550 |

Max. compression test space (mm) | 550 |

Cabinet dimension(mm) | 1200*620*850 |

Frame dimension(mm) | 1000*660*2400 |

Weight | Approx.3500kgs |

Column net distance (mm) | 580 |

Power supply (KW) | 380V 50HZ |

Safety devices | Software and machinery protection |

Span of bending roller (mm) | 400 |

Width of bending roller (mm) | 140 |

Diameter of bending roller (mm) | Φ40 |

Compression platen size (mm) | 200*200 |

Max. piston stroke (mm) | 250 |

Piston max. speed (mm/min) | Approx.80 |