Casting auto parts & construction parts

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300~400T per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Casting Steel Replacement Parts, Casting Stainless Spare Parts, Casting Alloys Spare Parts, Heat Resistant Steel Casting Parts, Stainless Steel Investment Castings |

Product Detail

| Model No.: | casting019 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FY or OEM |

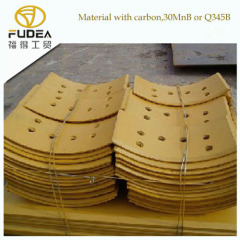

| Material: | Low Alloy Steel |

| Colour: | According to customer's option |

| Dimension: | Customization |

| MOQ.: | 100PCS |

| Price Term: | FOB, CIF |

| Shipment: | By sea |

| Place of Origin: | Ningbo, China |

| Production Capacity: | 300~400T per month |

| Packing: | Wooden cases or According to customer's requirement |

| Delivery Date: | 30-45 days |

Product Description

We can produce customization casting products with low alloy steel and high alloy steel.

Strict quality control ensures superior products. For each production, we strictly perform microstructure analysis and composition test for the material, by which guarantee us the right content and purity.

1.Develop new products process (customization)

Confirmation:First confirm if it's possible to develop customer's new products, if "YES", the Research and Development Department will evaluate the develop time and product cost according information which be offered by sales department.

Make new product development plan: the Research and Development Department, QC department, Sales department, Production department work together.

Design product graphics.

Design mould.

Evaluate the design.

Mould manufacturing.

Test the mould.

Test the samples.

Send the samples to customer.

Customer confirm the sample.

Batch production.

Materials: Carbon Steel, Alloy steel, Stainless steel, High Manganese steel, Gray Iron, Ductile cast iron,Resistance cast iron, High Cr Cast iron, Resistance steel, and etc.

Main equipment: Wax injection, CNC-machine, machine-center, Heat treatment Furnace etc.

Surface treatment: After casting, we can do machining, polishing, oiled (rust-proof), zinc, nickel, chrome plating, hot galvanized, painted.

Suitable for:Mining & earthmoving equipment components, heavy construction machine, agricultural machine etc.

17 years manufacturing experience.

Good quality and reasonable price.

Factory directly supply.

100% test before shipment.

7x24h good after-service.

Welcome to contact with us, looking forward to cooperate with you, thanks.

2.Features:

We can offer one-solution service on investment castings from tool designing & developing, casting, machining, finishing, assembling, packing and shipping after you designed it. You name it, we make it.

3.Our Advantage:

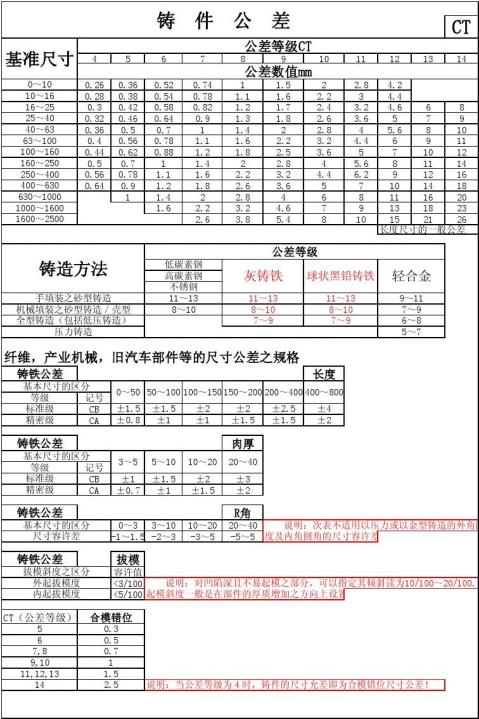

4.Casting Tolerances:

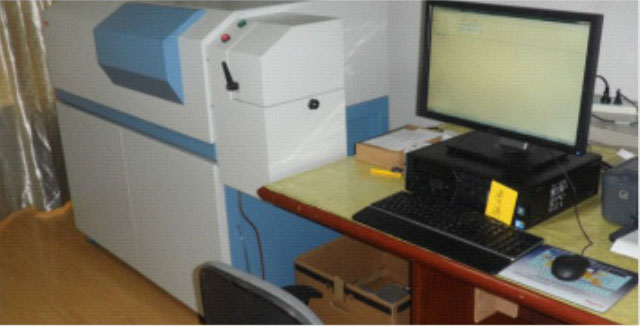

5.Inspection Equipment:

Direct-reading Spectroanalysis instrument

A. Usage: Inspecting and analyzing chemical composition.

B. Inspecting chemical composition before and after pouring.

Testing bar keeps at least 2 years which means that we can trace over two years about the casting parts.

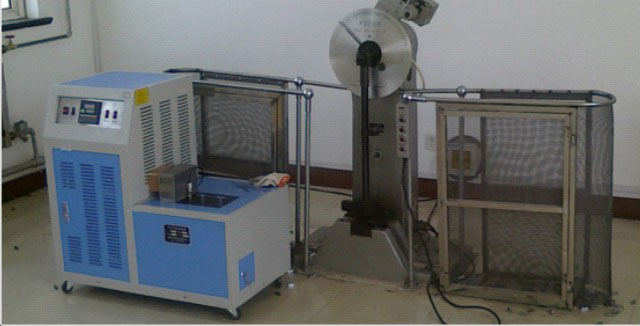

Impact Testing Machine

A. Usage: Normal temperature and low temperature.

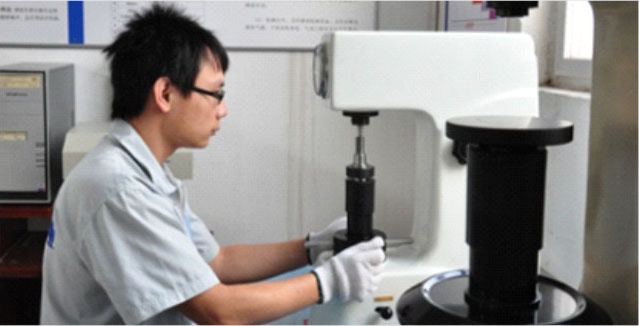

Brunel Hardness Tester

Noumenal testing Grinding 1-2mm in the surface and testing each heat treatment stove.

Ultrasonic testing Instrument

A Steel casting: FB7233-87

B Inner flaw testing.

Hydraulic Universal Tensile Strength Testing Machine

A Usage: Inspecting Tensild, Yield, Elongation and Reduction.

B Range: 0-600KN.

.jpg)