Industry Dryer Desulfurization Gypsum Drying Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50set/year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Saw Dust Briquette Machine, High Briquette Machine, Iron Powder Briquette Machine, Dry Powder Briquette Machine, |

Product Detail

| Model No.: | FYD-3m x 20m |

|---|---|

| Means of Transport: | Ocean |

| Model: | FYD-3m x 20m |

| Capacity: | 25t/h |

| Power: | 55kw |

| Production Capacity: | 50set/year |

| Packing: | 40'GP |

| Delivery Date: | 30days after confirm the order |

Product Description

Product Introduction

With the increase of environmental protection consciousness, our country to the power plant coal gas in the sulfur dioxide emissions control is getting more and more tight, power plant desulfurization is imperative. At present, the treatment process and equipment of FGD gypsum are not the same as the natural gypsum, such as in the material conveying, dust treatment, combustion process, etc.. On physical desulfurization gypsum and natural gypsum also has the difference, such as high desulfurization gypsum purity, free water, fine particle size; particle size uniform particle size distribution, poor gradation, standard thick by a large amount of water, the water soluble salt more. It is also worth noting is different from the source of gypsum and natural gypsum, FGD gypsum to unreacted calcium carbonate as main impurities and is not complete oxidation of sulfite calcium exist, impurity state difference, and the other in the production process of desulfurization technology for the treatment of different limestone composition of raw materials, processing of the fineness of limestone different will affect the desulfurization gypsum quality.

Technological Superiority

The main application of the desulfurization gypsum is the use of it as a cement retarder; or a half water gypsum is used in the manufacture of gypsum board. The two kinds of direct method and indirect method can be divided into different types of building gypsum.

1.Indirect method (two steps of drying calcination)

The drying, and claiming two-step method is according to the requirements of the power plant's energy and environmental protection, it will be much easier to prolapse of free water and difficult to prolapse of crystal water set in the two sets of equipment to make it more reasonable, but also facilitate the adjustment of product structure and quality control. The device can produce dry two water gypsum (cement retarder used), super fine plaster.

2.Direct method (one step method for drying calcination)

One step method of drying and calcination is a set of gypsum and calcined process equipment for the research and development of the three - story roller drying equipment with high efficiency of heat and mass transfer. The process device can produce dry two water gypsum (cement retarder used), also can produce semi water gypsum, production of dry two water gypsum of the wind temperature just 120 can use the thermal power plant of low temperature flue gas.

Prospects for Development

Desulfurization gypsum in building materials industry is widely used, through different means to deal with, basically can replace most of the use of natural gypsum production of building materials products. The integrated treatment and application of domestic desulfurization gypsum has started, the utilization prospect of contains a huge market opportunity, especially the lack of the natural gypsum and gypsum resources rich in economically developed areas and the practical application prove desulfurization gypsum is a valuable resource for high grade. It can be applicable to different uses of gypsum building materials production, processing after the desulfurization gypsum is a even better than the natural gypsum cementations materials. Desulfurization gypsum after drying and dehydration treatment become plaster and plaster of Paris by the products can be divided into: casting gypsum, gypsum plaster, ceramic industrial gypsum, plaster casting industry, the tooth material with gypsum and orthopedic medical bandage gypsum, coal mine fire prevention to strengthen tunnel wall plaster, soil improvement Liang with plaster, and so on, the largest amount of is building plaster (plaster of Paris).

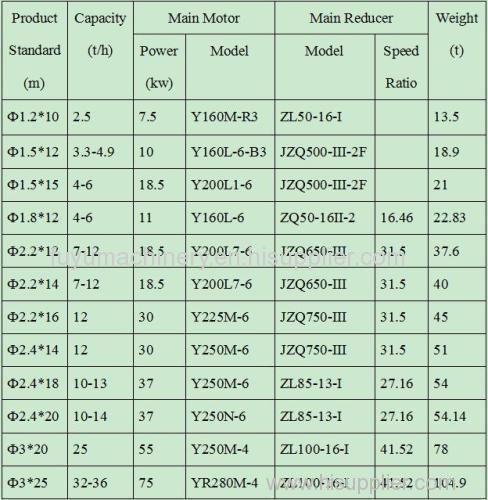

Technical Parameters

Contact Us

Sales Manager: Holly

Web: www.ball-press-machine.com

Email: fuyumachine@yahoo.com

Tel: 0086-371-85613608

MoB: +8618538292735

Skype: hollyhoh_0115

Address: Xiaoyi industry district, Gongyi city, Henan province, China