High Quality Green Sand

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 30,000 tons per year |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | High Quality Chromite Sand Service, Ceramsite For Aluminum Casting Sale, Green Sand Factory Price, High Quality Casting Sand Price, High Quality Foundry Coating |

Product Detail

| Model No.: | AFS 39 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Kailin |

| Shape: | Spherical |

| Color: | Brown |

| Refractoriness: | 1800℃ |

| PH: | 7-7.3 |

| Grain size distribution: | AFS 20~ AFS 180 |

| Application: | foundry ,casting, resin coated sand |

| Bulk density: | 1.95~2.05(g/cm3) |

| Mohs'hardness: | 6.5~7.5 |

| Production Capacity: | 30,000 tons per year |

| Packing: | 1000kgs bag |

| Delivery Date: | Within 15 days of receipt of the advance payment |

Product Description

We are seeking global co-operation agents for our products.

Chemical &Physical Index

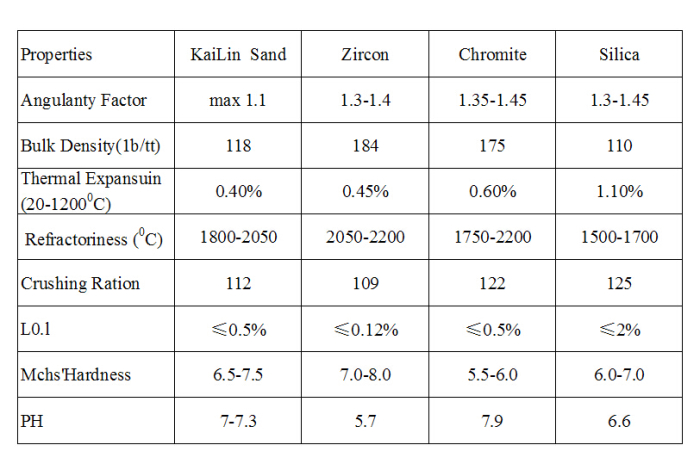

Properties of Kalin Ceremic Sand (Compared with other special Sand)

Application of Ceramic Sand

Casting Mold

Factory Buldings

Equipment Photo

Technical Support

Anything wrong happening in our products will be solved within one day; we always offer relative technical support/consultant quick response and all your inquiry will be replied within 24 hours.

The Main Market

Our Products and service are sold well in Japan, North America, South Korea ,Europe and other Countries.

SGS

FAQ

Q1:What is the lead time ?

A:Sample is 3~5 days, mass production time is about 10~15days .

Q2.Do you have any MOQ limit?

A:Our MOQ is one container includes 20 tons.

Q3:Are you manufactory or trading company?

A:We are manufactory.

Q4: What kind of your products?

A:Our main products is ceramic sand .

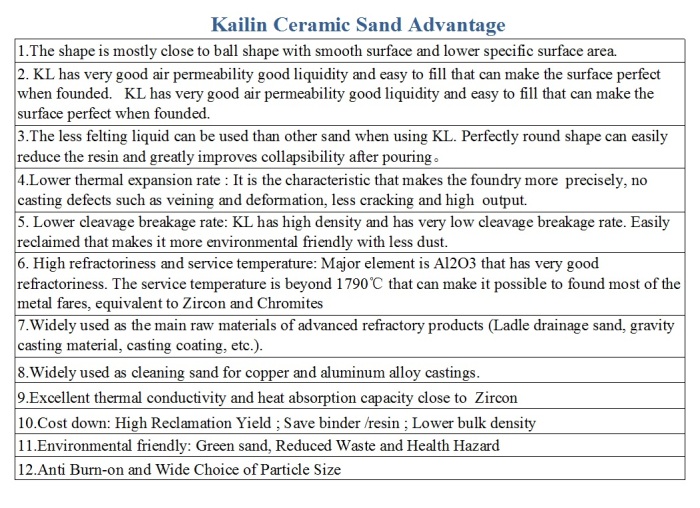

Why ceramsite?

1.Prevention of sand expansion defects, especially finning veining;

2.Elimination of gas-forming additives;

3.Prevention of reactions between metal and moulding sand;

4.Prevention of metal penetration;

5.Reduction of core weight;

6.Improved flowability of the moulding sand;

7.Influence on the formation of microstructure;

8.Pouring of thin-walled castings.