Ceramsite For Aluminum Casting Sale

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,DDP,DAP,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30,000 tons per year |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | High Quality Chromite Sand Service, Ceramsite For Aluminum Casting Sale, Green Sand Factory Price, High Quality Casting Sand Price, High Quality Foundry Coating |

Product Detail

| Model No.: | AFS 45 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Kailin |

| Shape: | Ball |

| Mohs'hardness: | 6.5~7.5 |

| Bulk density: | 1.95~2.05(g/cm3) |

| Application: | foundry ,casting, resin coated sand |

| Grain size distribution: | AFS 20~ AFS 180 |

| PH: | 7-7.3 |

| Refractoriness: | 1800℃ |

| Color: | Brown |

| Production Capacity: | 30,000 tons per year |

| Packing: | 1000kgs bag |

| Delivery Date: | Within 15 days of receipt of the advance payment |

Product Description

We are seeking global co-operation agents for our products.

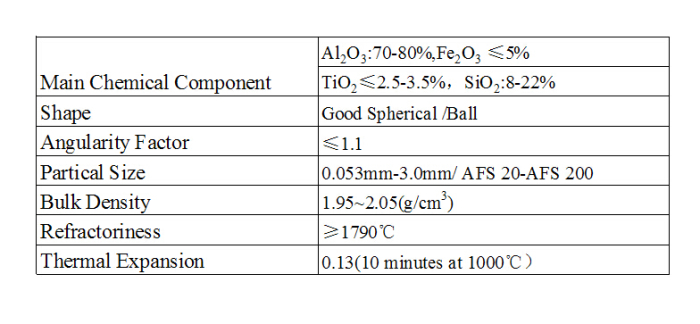

Chemical &Physical Index

Properties of Kalin Ceremic Sand (Compared with other special Sand)

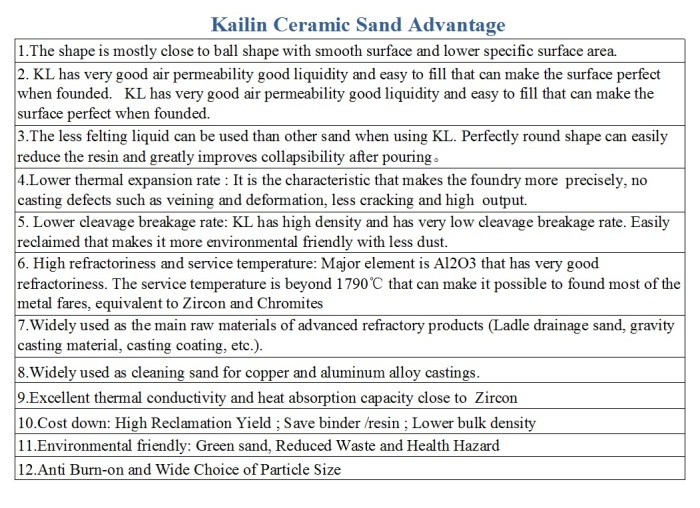

Kailin Ceramic Sand Andavage

1. Round solid Ball shape: The shape is mostly close to ball shape with smooth surface and lower specific surface area. And KL has very good air permeability good liquidity and easy to fill that can make the surface perfect when founded. Furthermore, KL can flow very easily and easy to clean. The less felting liquid can be used than other sand when using KL.

2. Lower thermal expansion rate and thermal conductivity: It is the characteristic that makes the foundry more precisely, less cracking and high output.

3. Lower cleavage breakage rate: KL sand has high density and has very low cleavage breakage rate. Easily reclaimed that makes it more environmental friendly for with less dust.

4. High refractoriness and service temperature: Major element is Al2O3 that has very good refractoriness. The service temperature is beyond 1790℃ that can make it possible to found most of the metal fares..

5.Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.).

6.Widely used as cleaning sand for copper and aluminum alloy castings.

Application of Ceramic Sand

Casting Modle

Factory Buldings

Equipment Photo

Application :

1.Widely used in foundry technique like resin -bonded sand,

sodium silicate sand, and clay- bonded sand for sand core and casting mould making.

2.Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine.

3.Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand). 4.Widely used as dry sand and sand box for EPC process and V method of casting processes. 5.Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.).

6.Widely used as cleaning sand for copper and aluminum alloy castings.

Technical Support

Anything wrong happening in our products will be solved within one day; we always offer relative technical support/consultant quick response and all your inquiry will be replied within 24 hours.

The Main Market

Our Products and service are sold well in Japan, North America, South Korea ,Europe and other Countries.

SGS

FAQ

Q1:What is the lead time ?

A:Sample is 3~5 days, mass production time is about 10~15days .

Q2.Do you have any MOQ limit?

A:Our MOQ is one container includes 20 tons.

Q3:Are you manufactory or trading company?

A:We are manufactory.

Q4: What kind of your products?

A:Our main products is ceramic sand .

![[Aluminum Casting for sale]Complex aluminum casting process](http://img.hisupplier.com/var/userImages/2019-08/22/094530263_240.jpg)