Casting Covering Flux Price

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 tons per year |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | High Quality Chromite Sand Service, Ceramsite For Aluminum Casting Sale, Green Sand Factory Price, High Quality Casting Sand Price, High Quality Foundry Coating |

Product Detail

| Model No.: | KL-HA07 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Kailin |

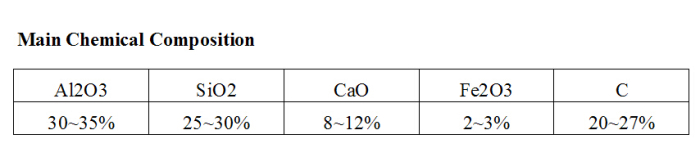

| moisture: | 0.3~2% |

| Grain size: | ≤1.5mm |

| Melting temperature: | 1200~1250℃ |

| Expansion: | 2~3 |

| Density: | 1.1g/cm3 |

| application: | Riser |

| Shape: | Powder |

| Packaging Details: | by you option |

| covering flux: | High refractoriness |

| Production Capacity: | 10000 tons per year |

| Packing: | 1000kgs bag |

| Delivery Date: | Within 15 days of receipt of the advance payment |

Product Description

We are seeking global co-operation agents for our products.

High-Aluminum Riser Insulating Covering Flux

Covering Flux can be repeatedly reused since it has better hardiness and durability compared to silica sand. For this reason, Covering Flux benefits not only the foundry industry, but also contributes to the preservation of natural sand resources in rapidly growing countries. Since Riser Insulating Covering Flux has higher thermal conductivity and excellent chilling characteristics than other products ensures higher reusability.

Features

Features

Features

1.low rebound rate

2.high strength

3.small shrinkage

4.powerful workability and durability

Application

Very low thermal expansion ensures fewer or no casting defects such as veining and deformation

Factory Building

Equipment Photo

FAQ

Q1:What is the lead time ?

A:Sample is 3~5 days, mass production time is about 10~15days .

Q2.Do you have any MOQ limit?

A:Our MOQ is one container includes 20 tons

Q3:Are you manufactory or trading company?

A:We are manufactory.

Q4: What kind of your products?

A:Our main products is ceramic sand .

Features

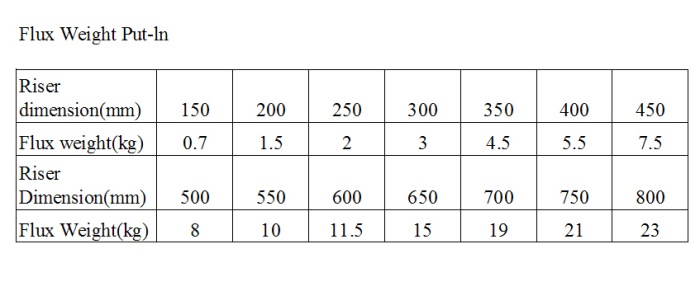

1.Using high-aluminum insulating refractory material,the covering flux has high calorific value and good performance of heat insulation.

2.This covering flux can lead an "U" shape section riser bottom showing that the casting shrinkage has been well compensated.So the foundry can save 30~50% molten steel.