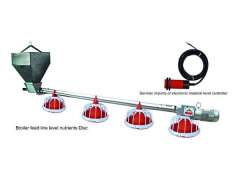

Huabo Broiler Pan Feeding System

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Poultry Farming Equipments |

Product Detail

| Model No.: | HB-Broiler pan |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Huabo |

| Name: | Huabo Broiler Pan Feeding System |

| Color: | yellow |

| Material: | PP |

| User: | broiler chicken |

| Diameter: | 330mm |

| Grille: | 14 grilles |

| Service life: | 15 years |

| Type: | End control pan,mechanical movable pan,feed pan with sensor |

| Number of birds per pan: | 40-60 birds/pan |

| Grille hole size: | 60mm |

| Production Capacity: | 5000sets per month |

| Packing: | Packed in cartons |

| Delivery Date: | Within 20 days |

Product Description

Huabo broiler pan feeding system offer you experience for no worry from day old to slaughter.

Advantages

1. Feed pan is ideal for whole raising period from brooding to slaughter.The suitable pan

height is easy to get feed.360° feed distribution improve uniformity.

2. Special designed feed cone with wings prevents feed waste.

3. Control pan ensure fresh feed supply,provide hygienic feed to birds and excellent feed

conversion rate.

4. Convenient adjustment of feed level.

5. Feed pan is available to rotate 360 degrees,available to swing vertically or fix without

rotation.

6. Optional shut-off slide,suitable for partition feeding.

7. Special hinged-type opening at bottom for easy cleaning and disinfection.

8. Adjustable feeding line of optional position for different period birds.When cleaning,easy to lift.

Technical Specification

Final weight 1.8kg | Final weight 1.8kg-3kg | |

Birds/pan | 57-91 | 57-85 |

Density(birds/㎡) | 16-20 | 12-16 |

Max daily feed intake | 170g | 175-220g |

Product specification | ||

Feed pan | Diameter | 330mm |

Material | pp | |

Pan capacity | 300g | |

Number of grill | 14 | |

Grill hole size | 60mm | |

Pipe&auger | Material of pipe | Hot galvanized |

External diameter of auger | 45mm | |

Distance between feeder | 1000mm 750mm | |

Max feeding length | 150m | |

Drive motor | Drive motor specification | 1.1kw 380v 50hz 0.75kw 380v 50hz |

Delivery capacity | ≥450kg/h | |

Hopper | Capacity | 70kg |

Details

1. Hopper for broiler pan feed line

Hopper location: hopper installed at the end of the feed line or middle of the feed line to

realize automatic feed delivery,feed delivered equally to each feed pan.

Hopper installed at middle of pan feed line for fast feed delivering from hopper to each feedpan for those long length feeding lines.

2. Hopper feed level controller

Using feed lever sensor or micro-switch in hopper for automatic feed lever controlling.

To control drive motor on-off,when there is feed in hopper,motor will be on for movement,when the feed in hopper

under micro-switch,motor will be off for movement,this device forbid motor keeping movement when

there is no feed in feed pipe.

3.Sectional brooding using AFS feed level sensor

Feed controlling with feed sensor to satisfy sectional brooding needs.

During brooding period, generally AFS feed level sensor is placed in the fourth or fifth pan of brooding district to realize sectional birds brooding.

4.Brooding using partial feeding lines

Using partial feeding lines for brooding,during brooding period, the sensor is placed at the

front of the end control pan.

5.Hopper capacity

We have 70kg hopper,90kg hopper and 120kg hopper for broiler pan feed line.

Using extension parts to increase hopper capacity to meet with clients request for large

capacity hopper.

6. Feed line hanging system

For hanging rope,we have 3mm stainless steel wire,3mm galvanized wire,as well as 6mm nylon rope for clients' request.We recommend 6mm nylon rope better.

7.Feed line lift with manual winch or automatic winch

Using automatic winch to realize automatic lifting,labor saving.

Using manual winch together with hand crank for feed line lifting.

8.Feed pipe connector

Using pipe clamp to fix feed pipe together.

9. Motor for broiler pan feed line

We have Two types motor for client's choice.

Split-type motor and integrated-type motor,we recommend splittype motor better, which save maintenance cost for long use.

10. Huabo broiler feed pan

Huabo broiler feed pan Idea design for birds from day old to slaughters.

Special design of the pan prevents feed spillage and waste,feed saving.

Feed pans made of high quality PP with 100% raw material.

Specification of Huabo broiler feed pan

Feed pan | Diameter | 330mm |

Material | pp | |

Pan capacity | 300g | |

Number of grill | 14 | |

Grill hole size | 60mm | |

Birds/pan | 40-55 birds | |

Color | Yellow(Color can be customized) |

Spare parts for Huabo broiler feed pan

| Fantastic start up of day-olds 1.A low pan edge for easy access to the feed 2.The special grill design keeps young birds out of the pan from 10 days onwards 3.The control unit ensures a fast and frequent delivery of fresh feed, leading to superior hygiene and outstanding feed conversion rates.

|

| Handy feed level adjustment ring Control different feed level in pan. 6 level settings |

| Feed cone The special cone wings prevent birds from flicking the feed. With feed windows and wings prevent feed spillage. Anti-swing.

|

| Pan bottom The undulated ring pan bottom perfectly keep feed inside with less feed wasted. Easily washing through high pressure water. Height: 53mm Double ring design Large feed trough

|

|

14 feed grilles 14 grilles with perfect distance to broiler. Strong enough for long time using. Lets birds line up around the pan

|

| Shut-off slide Could manually adjust the shut-off slide when there is no needed feed in one pan. To control feeds flow.

|

| Pan head Strong connection to feeder tubes

|

Using in farm