CVD Diamond Coated Nano Diamond Coating Wire Drawing Die for Drawing High Smoothness Aluminium Alloy

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, Money Gram |

| Supply Ability: | 5000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | diamond dies |

|---|---|

| Means of Transport: | Air |

| Product Material: | Steel |

| Product: | Others |

| Shaping Mode: | Extrusion Mould |

| Brand Name: | IW |

| Product Name: | CVD Diamond Coated Dies |

| Application: | Wire Drawing Industry |

| Mould material: | Chemical Vapor Deposition Diamond |

| Production Capacity: | 5000 |

| Packing: | Carton/ OEM pack |

| Delivery Date: | 10 |

Product Description

CVD Diamond Wire Drawing Dies | ||||||||||

| ||||||||||

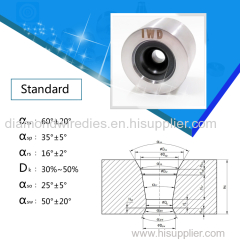

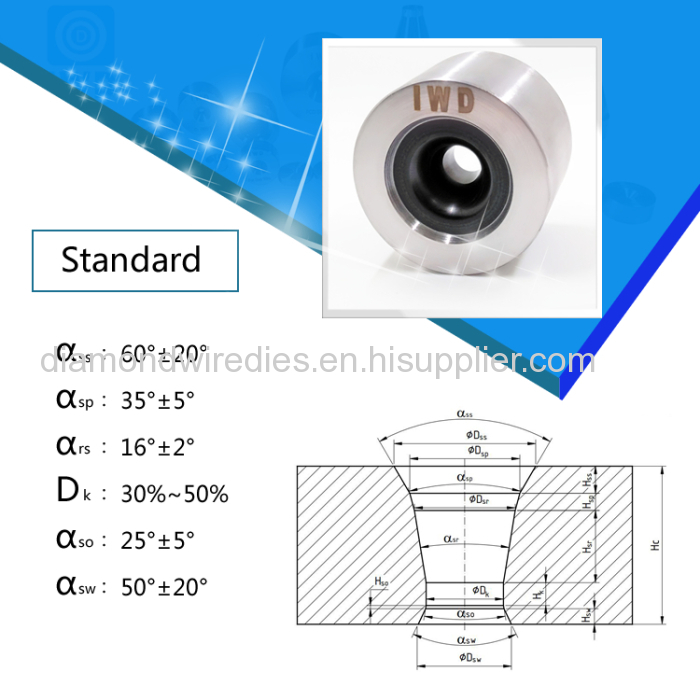

| α(ss)Entrance | The inlet area is polished so that the drawing fluid can circulate smoothly |

| α(sp)Approach | The lubrication area is finely polished, so that the wire can be easily excessive |

| α(rs)Reduction | The working area can reduce the drawing force, and the change-point contact is face-to-face angle drawing, which reduces friction and die wear. The deformed structure is more reasonable and stable. The upper line can be drawn smoothly when the incoming line becomes thicker or thinner. |

| d(k)Bearing | The fixed warp area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time. |

| α(so)Back Relief | The safety angle can ensure that the wire is drawn without scratches, and the life expectancy tends to be longer. |

| α(sw)Exit | The deepening of the outlet can greatly support the tensile stress of the outlet. |

The best material depends on the wire you draw and the quantity you draw. Contact us to help you choose the most economical solution and reduce the total cost of ownership of your drawing dies. In the center of the drawing die, there is a hole of a certain shape, such as round, square, octagonal or other special shapes. When the metal is pulled through the die hole, the size becomes smaller and even the shape changes. | |

Tolerance

Diameter(inch) | Diameter(mm) | Tolerance(mm) | Roundness(mm) |

≤0.00157 | ≤0.040 | 0.0003 | 0.0002 |

0.00158-0.00393 | 0.041-0.099 | 0.0005 | 0.0003 |

0.00394-0.01968 | 0.100-0.499 | 0.001 | 0.0005 |

0.01969-0.03936 | 0.500-0.999 | 0.0015 | 0.0008 |

0.03937-0.05905 | 1.000-1.499 | 0.002 | 0.001 |

0.05906-0.08661 | 1.500-2.199 | 0.003 | 0.0015 |

0.08662-0.12992 | 2.200-3.299 | 0.004 | 0.002 |

0.12993-0.18110 | 3.300-4.599 | 0.005 | 0.0025 |

0.18111-0.22834 | 4.600-5.799 | 0.006 | 0.003 |

0.22835-0.29921 | 5.800-7.599 | 0.007 | 0.0035 |

0.18111-0.41338 | 4.600-10.499 | 0.008 | 0.004 |

CVD (Chemical Vapor Deposition) coated wire drawing die is a new technology that has been developed recently, and its main method is to coat diamond film on the hard alloy wire drawing die.

The diamond film is pure diamond polycrystalline. It not only has the smoothness and temperature resistance of single crystal diamond, but also has the advantages of polycrystalline diamond wear resistance and low price. It has achieved good results in replacing rare natural diamonds in the preparation of wire drawing die tools. Its wide use will bring new vitality to the wire drawing die industry.

According to the types of materials, the wire drawing dies can be divided into alloy steel dies, cemented carbide dies, natural diamond dies, polycrystalline diamond dies, CVD diamond dies and ceramic dies.