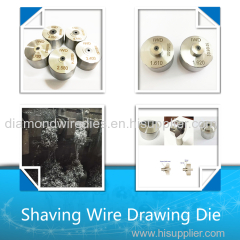

Customized High Quality Polycrystalline Diamond Shaving Dies;PCD shaving dies

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, Money Gram |

| Supply Ability: | 5000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | diamond dies |

|---|---|

| Means of Transport: | Air |

| Product Material: | Steel |

| Product: | Others |

| Shaping Mode: | Die Casting |

| Brand Name: | IW |

| Product Name: | PCD shaving dies |

| Surface treatment: | Polishing |

| Certification: | ISO 9001 |

| Production Capacity: | 5000 |

| Packing: | Carton/ OEM pack |

| Delivery Date: | 10 |

Product Description

Polycrystalline Diamond Shaving Dies Tungsten carbide (TC) insertion mold is widely used in peeling applications,but TC peeling mold is not relatively life-long,and the smooth surface and high-precision control performance are good. | ||||||||

|

Diamond Shaving Dies

The load-bearing area of polycrystalline diamond peeling die supports the vibration of wire material.It is much better to peel the wire surface through PCD mold than by a TC peeling mold.

The bearing area of PCD shaving dies support shaved wire materials against the vibration,the wire surface shaved by a PCD die is much better than that shaved by a TC dies.

The lifetime of PCD shaving dies provide 20 to 80 times (depending on materials) longer tool life than TC shaving dies.The long life reduces the setup time of exchange dies.

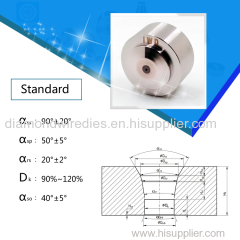

Tolerance

Diameter(inch) | Diameter(mm) | Tolerance(mm) | Roundness(mm) |

≤0.00157 | ≤0.040 | 0.0003 | 0.0002 |

0.00158-0.00393 | 0.041-0.099 | 0.0005 | 0.0003 |

0.00394-0.01968 | 0.100-0.499 | 0.001 | 0.0005 |

0.01969-0.03936 | 0.500-0.999 | 0.0015 | 0.0008 |

0.03937-0.05905 | 1.000-1.499 | 0.002 | 0.001 |

0.05906-0.08661 | 1.500-2.199 | 0.003 | 0.0015 |

0.08662-0.12992 | 2.200-3.299 | 0.004 | 0.002 |

0.12993-0.18110 | 3.300-4.599 | 0.005 | 0.0025 |

0.18111-0.22834 | 4.600-5.799 | 0.006 | 0.003 |

0.22835-0.29921 | 5.800-7.599 | 0.007 | 0.0035 |

0.18111-0.41338 | 4.600-10.499 | 0.008 | 0.004 |