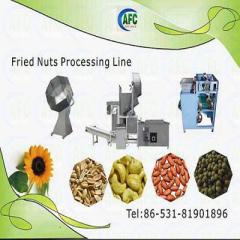

Fried Peanut Processing Line Introduction

Fried peanut processing line is used to produce delicious peanut and

broad beans, it includes blanching machine, peanut peeling machine,

broad beans opening machine, frying machine, de-oiling machine, flavoring machine and vacuum nitrogen packaging machine,

according to the different needs of the customers, it has large, medium

and small scale. If you have other special request for the fried peanut

processing line, we can also customize it for you as your request.

Fried Peanut Processing Line Processing Procedure

Fried peanut processing line the flowchart is as follow:

Peanut/broad beans— peanut kernel

blanching-- peanut kernel red skin peeling--opening (broad

beans)--peanut frying--fried nuts de-oiling--peanut flavoring—fried

peanuts packaging

1. The blanching machine is used to cook the peanut, let the peanut

kernel red skin easy to peeling and keep the nature flavor of the

peanut.

2. The peeling machine is a wet peeling machine, high peeling rate and no damage to the peanut.

3. For the broad beans, we should use the broad beans slitting machine for incision in order to make the beans easy to fry and can absorb the flavoring thoroughly and evenly.

4. Frying is a core step. The purpose of the frying is to reduce the

moisture in the peanut and get crispy peanut. When frying, please grasp

the right time, neither too early nor too late.

5. The fried peanut is placed into the de-oiling machine to extrude the spare oil.,the extruded oil can be use again to achieve the purpose of energy saving

6. The flavoring machine

is used to season the peanut which make the peanut more taste, the

customers can season various flavors according to their own intention.

7. The last step is packing. Vacuum nitrogen packaging machine can

finish large and high efficiency packaging. Through the packing, the

fried peanut can keep tasty and no damage for a long time.