multi pins header for sensor

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Glass To Metal Battery Cover, Battery Top Shell Seal Products, Glass To Metal Seal Products, Airbag Ignitors Provide Reliable Protection, Lithium Battery Top Shell Sealant |

Product Detail

| Model No.: | Customer design |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| high quality: | glass to metal |

| hermetically seal: | good insulation |

| Long lifetime: | High corrosion and chemically resistant |

| Excellent hermeticity: | Superior temperature performance |

| reasonable price: | best service |

| Production Capacity: | 1000 per day |

| Packing: | according to requirement |

| Delivery Date: | 15-30 days |

Product Description

1.Product Description

Multi-headers are often used in sensors applications, such as for rail industry. This industry requires rugged, moisture resistant sensors that can withstand high levels of vibration, impact and general mechanical abuse. The sensor header would have a die mounted to it that would monitor breaking, speed control, propulsion and head end power.

Product Advantages

Since 2000, we cooperated with many universities to develop the connectors used in aviation. After years' efforts, our products have been widely used in aviation and military for the good hermeticity and insulation resistance. The product well replaced the traditional rubber seal connectors.

Technology Specifications

l Hermeticity ≤1×1×10-9Pa.m3/s

l Insulation resistance≥ 5000 MegOhms @ 500 VDC

l No breakdown @ 1500V for 10S

l No leak @ 20MPa in 1minute

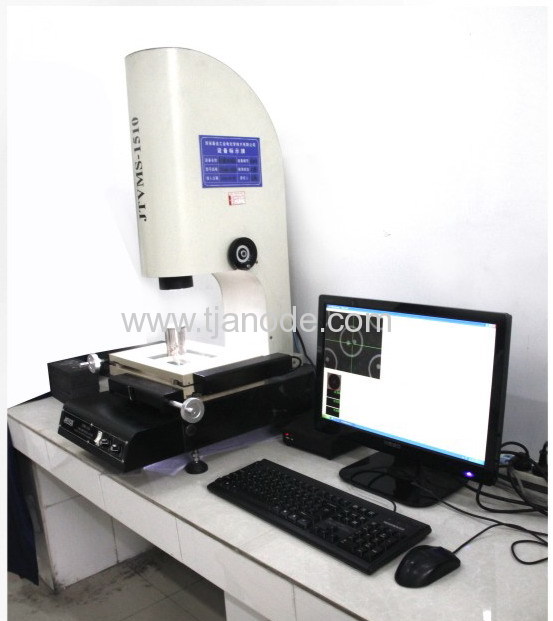

2.test equipment

3.quality certificate

Our total vertical integration includes:

1. Machining:

l Bodies, shells or metal housings: Inconel, Kovar and Nickel Alloys, Stainless Steel, Cold-Rolled Steel, Titanium

l Electrodes and contacts: Alloy 52, Inconel, Kovar, Molybdenum, Stainless Steel

2. Stamping

3. Precision grinding and lapping

4. Glass sintering furnaces

5. 5 Furnaces for glass-to-metal sealing

6. Innovative electroplating technology, including:

l Nickel (3 types)/ Tin, Tin-lead, Hot Solder Dip, Electropolishing of stainless steel

l Complete chemical analysis capability

7. Inspection / Testing

l Statistical Process Control/Optical comparators

l Humidity testing

l Temperature Cycling

l Optical Measuring Machines

l Hermeticity validation to 1 x 10-11 cc/sec of helium at 1 atmosphere differential pressure

l Insulation resistance to 10 gigaohms at 500 VDC

l Salt spray