battery cover glass to metal

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100,000 per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Glass To Metal Battery Cover, Battery Top Shell Seal Products, Glass To Metal Seal Products, Airbag Ignitors Provide Reliable Protection, Lithium Battery Top Shell Sealant |

Product Detail

| Model No.: | Customer design |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| high quality: | Long lifetime |

| High corrosion and chemically resistant: | Excellent hermeticity |

| Excellent hermeticity: | Superior temperature performance |

| Hermeticity ≤1×1×10-9Pa.m3/s: | Insulation resistance ≥500MΩat DC500v |

| Production Capacity: | 100,000 per day |

| Packing: | according to requirement |

| Delivery Date: | 15-30 days |

Product Description

Product Description

Lithium thionyl chloride batteries are frequently used in areas with extreme environmental conditions, often involving highly demanding temperature profiles. In order to protect these comparatively sensitive batteries from such harsh conditions, the batteries are covered with hermetically sealed feedthrus designed for conducting high voltages.

Features

l Long lifetime

l High corrosion and chemically resistant

l Excellent hermeticity

l Superior temperature performance

Applications

These batteries provide power to a wide range of equipment, including: communications equipment, imaging devices, chemical agent monitors, and weapons systems.

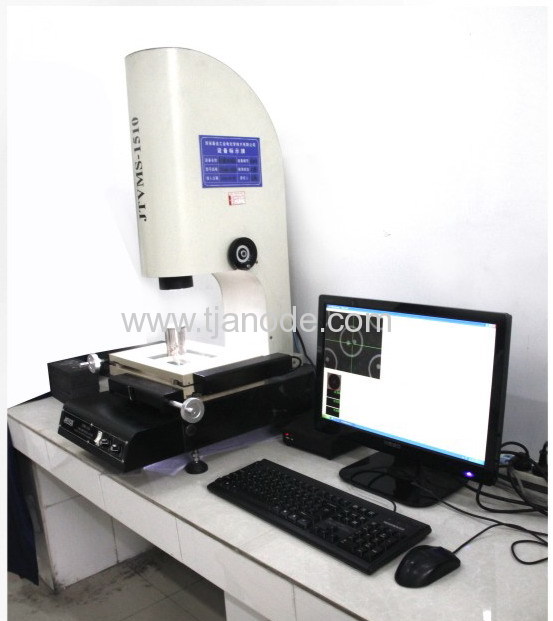

2.test equipment

3.quality certificate

Our total vertical integration includes:

1. Machining:

l Bodies, shells or metal housings: Inconel, Kovar and Nickel Alloys, Stainless Steel, Cold-Rolled Steel, Titanium

l Electrodes a l Electrodes and contacts: Alloy 52, Inconel, Kovar, Molybdenum, Stainless Steel

2. Stamping

3. Precision grinding and lapping

4. Glass sintering furnaces

5. 5 Furnaces for glass-to-metal sealing

6. Innovative electroplating technology, including: nd contacts: Alloy 52, Inconel, Kovar, Molybdenum, Stainless Steel

2. Stamping

3. Precision grinding and lapping

4. Glass sintering furnaces

5. 5 Furnaces for glass-to-metal sealing

6. Innovative electroplating technology, including:

l Nickel (3 types)/ Tin, Tin-lead, Hot Solder Dip, Electropolishing of stainless steel

l Complete chemical analysis capability

7. Inspection / Testing

l Statistical Process Control/Optical comparators

l Humidity testing

l Temperature Cycling

l Optical Measuring Machines

l Hermeticity validation to 1 x 10-11 cc/sec of helium at 1 atmosphere differential pressure

l Insulation resistance to 10 gigaohms at 500 VDC

l Salt spray