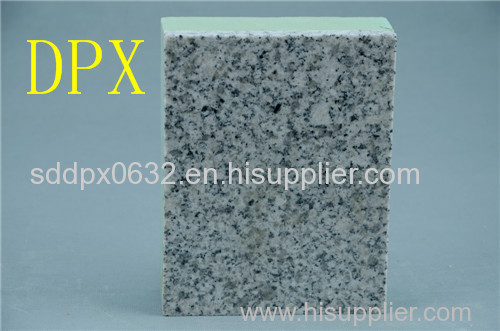

Decorative Thermal Insulating Materials Boards with Ultra-Thin Natural Stone Surface

Product Details:

Place of Origin: China

Brand Name: DPX Decorative Insulation Board

Certification: ISO9001

Model Number: DPX-2

Payment & Shipping Terms:

Minimum Order Quantity: 100.00 ㎡

Price: Negotiated

Packaging Details: Suitable for sea-freight Shipping

Delivery Time: 10 days after receiving pre-payment

Supply Ability: 10,000.00 ㎡ per month

Detailed Product Description

Decorative high strength thermal insulation board with ultrathin nature stone surface

Specifications:

Product Performance

Metal Fluorocarbon Painting Decorative Insulation

Board Decoration

Layer Ultrathin stone veneer decorative board Multifunction, light weight, high strength, easy to install and processing High quality, low cost, insulation, good decoration performance

Insulation Layer EPS insulation layer

(Grade B1) Heat conductivity ≤0.048. volume-weight :18kg / m³ with the tensile strength:110--120kpa; volume-weight 20kg / m³ with the tensile strength :140kpa.

XPS insulation Layer

(Grade B1) Heat conductivity ≤0.035. Volume-weight 25--45kg / m³ & tensile ≥150kpa. Strong compressive resistance. 30-40 years average using life. Excenllent structure load-bearing performance .

Polyurethane insulation board

(Grade B1) Hard polyurethane with low thermal conductivity, good thermal performance. When the hard polyurethane with the density of 35 ~ 40kg / m3, thermal conductivity is only 0.018 ~ 0.024w / (m.k), equivalent to half of the EPS, is the lowest heat conductivity of all the insulation materials .

TPS insulation board

(Grade B1) Heat insulation thermal conductivity is 0.060W / (m · k) ,it has good tensile compressive strength , impact resistance and stability ; its compressive strength reaches 150-500KPa

Rock wool (Grade A) Appearance quality: smooth surface, without prejudice practical scars, stains damaged. Combustion performance: non-combustible. Thermal load contraction temperature: 643 degrees.

Moisture absorption: 3.9%. Organic content: 2.9%.

Rockwool board basic parameters:

Material: rockwool

Apparent density: Rockwool 120 (kg / m3)

Heat conductivity: 0.04 (W / (m.K))

Max operating temperature: 80 (℃)

Specifications: 950,1150 (mm )

Operation standard: GB

Operating temperature: 80 (℃)

Phenolic Foam Board(Grade B Grade A) Not be melt at high temperatures ,not be softened, with low smoke, non-proliferation flame resistance, flame penetration, There is no distortion, no burning ,no fire, being placed 10 minutes at 1400 ℃, can effectively prevent the flames and smoke spread

DPX Decorative Insulation Board system performance index

Item Detection standard and requirements The third party test

results

Weather resistance JF149-2003,

JGG144-2004 After weather resistance test,

No damage such as facing layer

blistering or falling off,Protective

layer hollowing or falling off; No

seepage crack appear. No damage such as

facing layer blistering

or falling off,Protective

layer hollowing or

falling off; No seepage

crack

JG149-2003,

JGJ144-2004 Impact-resistance strength

grade:10

Water absorption

g/㎡,Immersed

24H JG149-2003,

JGJ144-2004 ≤500 21

Wind pressure

resistance value

KPa JG149-2003,

JGJ144-2004 Not less than the wind load

design value of the project After 15 kpa level wind

load esistance test,,no

water seepage

Freezing and

thawing resistance JG149-2003,

JGJ144-2004 No surface cracking,hollowing,

blistering,exfoliation No surface cracking,

hollowing,blistering,

exfoliation

Steam flow density g/(㎡·H) JG149-2003,

JGJ144-2004 ≥0.85 2.36

Watertightness JG149-2003,

JGJ144-2004 Sample protective layer inside

without water infiltration Sample protective layer

insidewithout water

infiltration

Thermal conductivity W/(m·k) GB/T10801.1-2002,

JG149-2003 ≤0.041 0.033

Apparent density

kg/m³ GB/T10801.1-2002,

JG149-2003 18.0-22.0 19

The compressive

strength perpendicular

to the panel MPa GB/T10801.1-2002,

JG149-2003 ≥0.10 0.10

Dimensional

stability % GB/T10801.1-2002,

JG149-2003 ≤0.30 Length Change 0.13

Width Change 0.15

Thickness Change 0.24

Compression

strength KPa GB/T10801.1-2002,

JG149-2003 ≥60 99

Water vapor

permeability

ng/(Pa·㎡·s) GB/T10801.1-2002,

JG149-2003 ≤60 4

Water absorption

(Volume fraction)% GB/T10801.1-2002,

JG149-2003 ≤6 2

Tensile bond strength MPa

(Connected with

cement mortar) Original intensity JG149-2003 ≥0.60 0.94

Water resistant JG149-2003 ≥0.40 0.54

Tensile bond strength MPa

(Connected with Expanded

polyphenyl board) Original intensity JG149-2003 ≥0.10,Destroy interface on

EPS Board ≥0.10,Destroy interface

on EPS Board

Water resistant JG149-2003 ≥0.10,Destroy interface on

EPS Board ≥0.10,Destroy interface

on EPS Board

Operational time

H JG149-2003 1.5-4.0 4.0

Single anchor bolt

tensile standard

capacity KN JG149-2003 ≥0.30 0.83

Description:

Description:

Decoration Veneer Layer: Ultrathin Nature Stone

Carrying Layer: Calcium silicate board;Cement pressure plate;Aluminium plate

Insulation Layer: Polyurethane plate

Ultra thin stone decorative insulation board, also called as exterior wall thermal insulation insulation

composite panels, composite insulation composite panels, granite stone, and so on, is composed by

the thin natural stone and insulation material. According to the decorative surface it can be divided

into paint and non paint, and the non paint can be mainly divided into ultrathin stone material and

ceramic tile, etc.

Applications:

Business Organizations It is widely used in office building,hotel, High-end residential and other building's decoration and insulation project.

Competitive Advantage:

1.Multi-function;

2.Light weight,;

3.High strength;

4.Highly decorative

5.Low cost, easy process etc

Contact Details

Shandong Horizon Building Energy Efficiency Technology Co.,Ltd.

Contact Person: Ms. Cai

Tel:+86-0632-8095666

Fax:86-0632-7775688

Description:

Description: