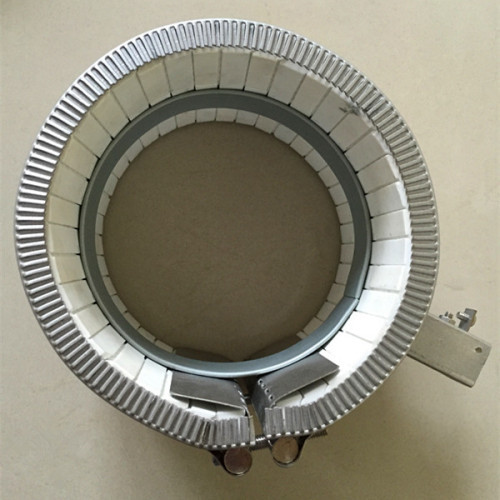

Industrial high temperature air heating element ceramic band heater

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,EXW |

| Payment Terms: | T/T, WU, Money Gram |

| Supply Ability: | 500000 |

| Place of Origin: | Fujian |

Company Profile

| Location: | Putian, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Heating Element, Cartridge Heater, Tubular Heater, Coil Heater, Teflon Heater |

Product Detail

| Means of Transport: | DHL/UPS/TNT, Ocean, Air |

|---|---|

| Category: | Industrial Heater |

| Capacity Type: | Light Duty |

| Certification: | CE |

| Brand Name: | Annai |

| Dimension(L*W*H): | Customized |

| Power(W): | Customized |

| Power Source: | Electric |

| Voltage(V): | 110-380V |

| Resistance Tolerance: | +5%, -5% |

| Sheath Material: | Copper, SUS430, SUS304, cast aluminum, cast |

| Wattage Tolerance: | +5%, -5% |

| Type: | ceramic band heater |

| Production Capacity: | 500000 |

| Packing: | Carton or Wooden case |

| Delivery Date: | 14 days |

Product Description

Industrial high temperature electrical air heating element ceramic band heater

Specifications

high temperature electrical air heater

1.Material:ceramic,brass,Mica

2.Certificate:CE,UL

3.Long work life

4.Factory prices

Product Description

These

heaters are available with various Energy saving options in various

sheathing materials, viz. Chrome Nickel Steel, Brass, MS, depending upon

applications which provides the best combination of physical

strength, high emissivity & good thermal conductivity to heat

cylindrical parts, good for sheath temperature up to 2500C.

Specification

Applicable

to the heating components in plastic forming, plastic granulating

machines, casting machines, and so on. We are experienced in heater

making, and we perform scientific selection of materials and product

manufacturing process design under the specific operation conditions of

equipment, which help improve the operation security and service life of

heating components.

Technique parameter:

1). Specification and size of heater: to be customized as required

2). Heater material: copper, SUS430, SUS304, cast aluminum, cast copper, ceramic, brass

3). Input power: to be customized as required

Characteristics:

1). Applying imported ray materials to ensure operation conditions of components under higher temperatures;

2). Using special manufacturing processes to enhance the heat radiation effect for components;

3). Good electric performance to meet the safety requirements of equipment;

4).

Taking the lead in manufacturing processes in the electric heating

industry to ensure the longer service life of electric heating parts and

components

Durable, ceramic band heaters provide excellent

energy efficiency with their built-in ceramic fiber jackets. Unlike mica

band heaters, ceramic heaters transfer heat through conduction and

radiation and do not require tightening around the cylinder. Flexible,

these heaters come in a wide variety of terminal styles, and with

different clamping mechanisms, holes and cutouts.

Features

• Nickel-chrome wire in a outer wall composed of interlocking ceramic tiles

• Inside medium-high temperature heaters up to 1200°F

• Outside shell temperature: 350° - 450°F

• Built-in ceramic fibre insulating mat

• Stainless steel jacket

•Minimum diameter: 2"

• Minimum width: 1"

• Thickness with ¼" insulation: 5/8"

• Regular gap: 3/8

• Maximum watt density: 45 w/in2

• Broad range of terminal types and thicknesses of ceramic fiber insulation mats

Application

• Injection molding

• Blow-molding

• Plastic extrusion

• Container, pipe, or tank heating

• Process applications

Why cooperate with us and What we can do for you?

1. Certificated by ISO9001:2000, CE

2. Low Prices Direct From Factory Suppliers.

3. Fast Delivery Around The Globe.

4. High Quality With Global Standards.

5. Goods must be passed QC and test before shipping out.

6. 1 year factory warranty.

7. Safe shipping way and payment.

8. Convenient & Friendly Customer Service.

9. Latest information and latest prices regularly info.

When you inquire,please supply some info as the following

1.Size (diameter, tubu length, cable length, cold zone) and shape

2.Voltage and power

3.Operation temperature requirement

4.Other design requirement

5.Order quantity

6.It's best you can supply drawing pics

Company profile

Shenzhen Annai Heating Element Co., Ltd, specializes in reserching, developing and manufacturing all kinds of high-end electric heating elements.

Our maintain products includes: Cartridge heater, coil heater, immersion tubular heater, band heater and sauna heater. All of our products are certificated by CE, ISOand UL. By virtue of our unique expertise and experience in electric heating technology, the products can be customized according to customers'different specifications and applications.

"Quality is our life, service is our soul!" Based on advanced technology, team work and professionalism, we can provide high-quality products as well as the most competitive price. ANNAI aims at offering the most reliableand professional service to our worldwide honorable clients.