Hydraulic Combined Punching and Shearing Machine price

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,EXW |

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 135 sets each month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | 400ton |

|---|---|

| Means of Transport: | Ocean, DHL, Air, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roller-Bending Machine |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | ISO 9001:2000 |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | CHINAPRIMA |

| Name: | iron punching and shearing machine |

| Name other: | angle channel cutting machine |

| Color: | optional |

| Hydraulics: | Taifeng |

| Motor: | Siemens |

| Electrics: | Schneiders |

| Sealing: | NOK, Japan |

| Delivery: | 5 days |

| Power: | 7.5kw |

| Quality: | CE |

| Production Capacity: | 135 sets each month |

| Packing: | Seaworthy packaging |

| Delivery Date: | 5 days after deposit. |

Product Description

Hydraulic Combined Punching and Shearing Machine price Hydraulic Combined Punching and Shearing Machine price

Sheet metal shearing and punching machinary Angle steel shearing and punching machinary Q35Y-30 angle steel shearing punching machine ironworker

Q35Y-16 hydraulic iron workers iron worker ironworker machine punch and shears machine

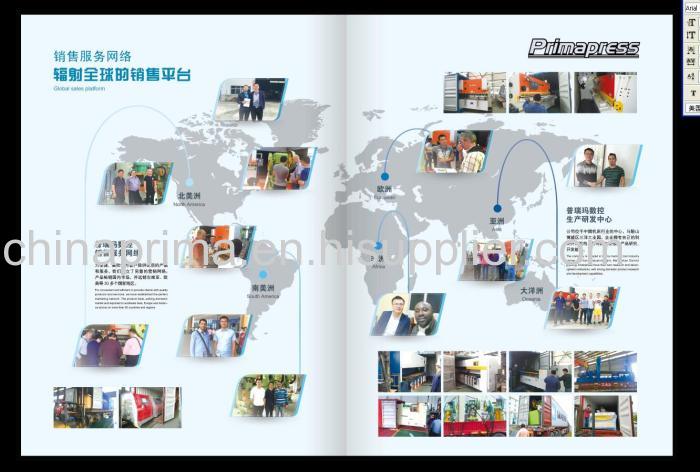

1,PrimaPress Company Ma'anshan Prima CNC Machinery Co., Ltd. is located in the center of China's machine tool industry, MaanShan BoWang District Sanyang Industrial Park. Our company specializes in presses machines, CNC shearing machine, CNC bending machine, CNC v cuttingmachines, all kinds of hydraulic machine, ironworker, rolling machine and other metal forming forging equipment development and sales, our product positioning in the middle-top quality class. We commit a modern enterprise management methods, committed management and meticulous management and zero defect operation. Based on the quality of the product management, its excellent quality, innovative design, reasonable price, and improve after-sales service to win the majority of Chinese and foreign customers praise. Primapress Brand products include: QC11Y, QC12Y, WC67Y, WE67K, W11, Y27, Y32, J23, J21, J21S, Q35Y more than 30 series over 200 varieties of sizes sheet metal processing equipment. Widely used in automobile manufacturing, communications, computers and so on. Prima CNC insist on leading technology strategy, positioning in the "do-class machine, a first-class brand," the high level of long-term sales of CNC machine tools in the process, not only to cultivate a number of series of numerical control products, while cultivating a group of skilled, practical style of high-quality workforce. Enterprises have their own research and development institutions, with the domestic strong product research and development of skills. Primapress specializes in the export business, the company already has CE certification, the products are widely exported to Southeast Asia, EU, South America, the Middle East and other markets, with good quality, suitable price, comprehensive after-sales service, was widely welcomed by customers and unanimously approved. Our company ambition is "build quality brand, do excellent machine",it is also the company's entrepreneurial spirit and look forward to domestic and overseas friends to visit.

Ma'anshan Prima CNC Machinery Co., Ltd. is located in the center of China's machine tool industry, MaanShan BoWang District Sanyang Industrial Park. Our company specializes in presses machines, CNC shearing machine, CNC bending machine, CNC v cuttingmachines, all kinds of hydraulic machine, ironworker, rolling machine and other metal forming forging equipment development and sales, our product positioning in the middle-top quality class. We commit a modern enterprise management methods, committed management and meticulous management and zero defect operation. Based on the quality of the product management, its excellent quality, innovative design, reasonable price, and improve after-sales service to win the majority of Chinese and foreign customers praise. Primapress Brand products include: QC11Y, QC12Y, WC67Y, WE67K, W11, Y27, Y32, J23, J21, J21S, Q35Y more than 30 series over 200 varieties of sizes sheet metal processing equipment. Widely used in automobile manufacturing, communications, computers and so on. Prima CNC insist on leading technology strategy, positioning in the "do-class machine, a first-class brand," the high level of long-term sales of CNC machine tools in the process, not only to cultivate a number of series of numerical control products, while cultivating a group of skilled, practical style of high-quality workforce. Enterprises have their own research and development institutions, with the domestic strong product research and development of skills. Primapress specializes in the export business, the company already has CE certification, the products are widely exported to Southeast Asia, EU, South America, the Middle East and other markets, with good quality, suitable price, comprehensive after-sales service, was widely welcomed by customers and unanimously approved. Our company ambition is "build quality brand, do excellent machine",it is also the company's entrepreneurial spirit and look forward to domestic and overseas friends to visit.

Machine Features:

1.Introduction to the structure and properties:

Q35Y Series hydraulic combined punching&shearing machine can cut and punch all kinds of materials such as plate, square bar, angle, round bar, channel and so on.Prima hydraulic ironworkers have been designed and built to the highest quality standards in the industry. This profitable machine will serve any grueling fabrication shop for decades to come. This machine is typically in stock for quick deliveries.

2.Equipment's working environment:

1 Power supply:3Ph AC 220V/380/415 ± 10%, 50/60 HZ, optional to site. 2 ambient temperature:-10 ℃ ~ 45 ℃ Q35Y-30 angle steel shearing punching machine ironworker

3.Main functions:

1)Punching: Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings.Quick change coupling nut and sleeve for rapid replacement of change.

2)Shearing: Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg. This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.Large 15″squaring arm with inlaid scale.Special anti-distorted blade for quality cutting.Lower blade has four usable edges.There is screw allow for gap adjust no shim needed.

3)Notching: Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic ironworker is perfect for notching out metal plate, angle iron and much more. The notching station also has an over sized table with material stops. This section of the machine can also be outfitted with the optional vee notcher.

4)Bending: Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safety, function.

Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 |

Ramming strength (ton) | 65 | 90 | 120 | 160 | 200 | 250 |

May cut the biggest thickness of slab | 16(millimeter) | 20 | 25 | 30 | 35 | 50 |

Sheet intensity (Newton/millimeter 2) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

A traveling schedule cuts the board size (thick * wide) (millimeter) | 16*250 | 20*330 | 25*330 | 30*330 | 35x400 25x700 | 40*400 30*750 |

Slide stroke | 80 | 80 | 80 | 80 | 80 | 80 |

Traveling schedule number of times (/minute) | 12 | 12 | 10 | 10 | 10 | 10 |

Throat opening depth | 300(millimeter) | 355 | 400 | 600 | 600 | 600 |

Punch holes thickness | 16(millimeter) | 20 | 25 | 26 | 35 | 40 |

Biggest punch holes diameter (millimeter) | 25 | 30 | 35 | 38 | 40 | 40 |

Main electrical machinery power (kilowatt) | 55 | 7.5 | 11 | 11 | 15 | 22 |

External dimensions (long * wide * high) millimeter | 1750*830*2000 | 1930*900*2000 | 2200*1000*2100 | 2900*1200*2600 | 2970*1240*2650 | 3200*1440*2750 |

Machine weight (kg) | 2000 | 2600 | 4600 | 7200 | 9500 | 12800 |

Certicates:

Safe Package:

Customers visiting factory:

Services:

1, 24 hours telephone line is available for any question.

2, Experienced service technician team is available.and can go abroad for training and commissioning.

FAQ:

⇒Are you a factory or trading company?

We are a factory with more than 10 years export experience. .

⇒Where is your factory located? How can I visit there?

Our factory is located in Anhui Maanshan Province(next to Shanghai),China.You can fly to Shanghai airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

⇒How does your factory do regarding quality control?

Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO,BV authentication.

⇒Trade Terms:

1.Payment: T/T,Western Union,MoneyGram,PayPal; 30% deposits;70% balance before deliverying.

2.Delivery Time: 5-60 days

3.MOQ: 1 pcs

⇒Why choose us?

1.We are China Leading Amada plegado de chapa de la maquina y la maquina de corte Manufacturer.

2.Alibaba Assessed 6 years Gold Supplier for Amada plegado de chapa de la maquina y la maquina de corte.

3.Inspected by the Inspection Institution of Bureau Veritas Certification.

4.100% QC inspection Before Shipmeng.

5.Best Quality & Best Service with Competitive price.