Top quality double-layer fully automatic LV transformer aluminium foil winding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 150 Sets Per Year |

| Place of Origin: | Jiangxi |

Company Profile

| Location: | Pingxiang, Jiangxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | APG Equipment & Mould, Foil Winding Mahcine, Coil Winding Machine |

Product Detail

| Model No.: | BRJ-1600/1400/1100 |

|---|---|

| Means of Transport: | Ocean, Air |

| Winding power: | 22KW /15KW |

| Maximum diameter of coil: | 800mm |

| Form of coil: | Square Rectangular Round |

| Winding speed: | 0-24r/min speed stepless |

| Welding speed: | 0-0.7/min speed stepless |

| Height of coil: | 300-1600mm |

| Activity scope of barrel: | 460/520mm |

| Feature 1: | Japan Mitsubishi PLC |

| Feature 2: | Clean device |

| Feature 3: | Engineer Overseas Service |

| Production Capacity: | 150 Sets Per Year |

| Packing: | Bubble film then into the wooden case |

| Delivery Date: | 45 days upon receipt of deposit |

Product Description

Top quality double-layer fully automatic LV transformer aluminium foil winding machine

Product Overview

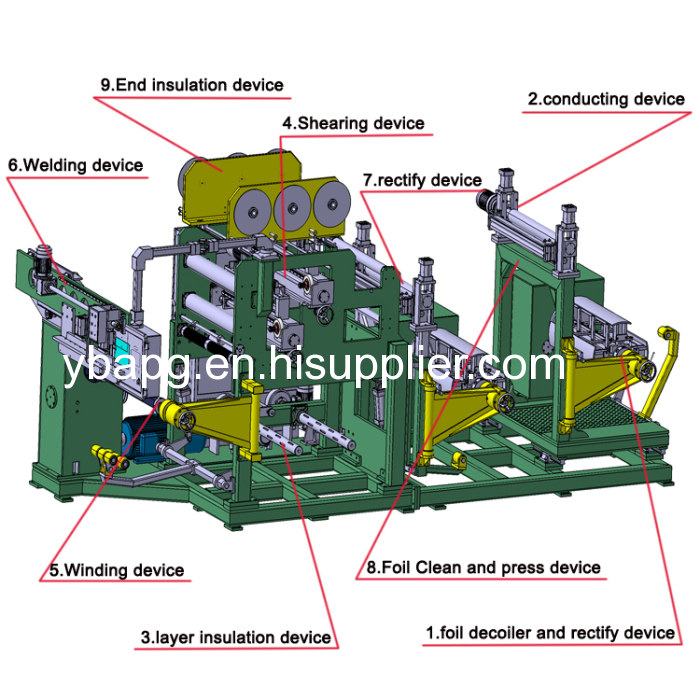

Structure:

BRJ Digital foil winding machine, special equipment used for transformer foil winding production, is produced by (cooper or aluminum) conductive materials. The device is newly developed by the company according to full understanding of the actual use of transformer based on high quality and usefulness of winding transformers. The product has high quality and efficiency with simple and reliable operation.

Overview:

Unwinding and rectification devices

Feeding device

Layer insulation device

Shear device

Winding device

Welding device

Photoelectric edge control device

Clean device

Pressure device

Electric control box

Argon tungsten-arc

Features:

Unwinding brake applies tension, the tension is stable and the Static and dynamic tension isconsistency, it is controlled by pneumatic components. Foil tape and insulation tape are applied with constant tension no matter it is winding or backing, in order to avoid uneven tightness coil by losing tension, the air pressure can be stepless adjusted, which ensure that the entire process of winding tension is stable.

Steps of Quality Control

1.Strictly control the purchase standard of raw materials.

2.With high precision equipment and rich experience workers to process components, make each process up to standard.

3.Assembly process, recheck the quality of the components, the machine appearance etc.

4.Before shipment, test all operating procedures by winding the core to ensure the machine work normally.

Package and shipping

Company information

1.The only manufacturer who can supply one-stop complete solution service for electric industry of resin products such as CT,PT,insulators,SF6 shell.with best factory price and fast shipment.

2.Professional rich experience engineers and research team, we offer free APG technique training.Our engineers have 23 years experience who serviced many years in ABB.

3.100% promise to teach APG technique to you even you are newcomer.

4.Have a line and lab special for producing CT and PT.we can winding samples and test in our lab.

Contact Information

Website:www.ybapg.com

Tel | What's App | Wechat:+86 188 24102415

Email | Skype:laura(at)ybapg.com