APG clamping Epoxy-resin automatic pressure transformer apg injection moulding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 150 Sets Per Year |

| Place of Origin: | Jiangxi |

Company Profile

| Location: | Pingxiang, Jiangxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | APG Equipment & Mould, Foil Winding Mahcine, Coil Winding Machine |

Product Detail

| Model No.: | APG-858 |

|---|---|

| Means of Transport: | Ocean, Air |

| Item: | Automatic APG Clamping machine |

| Feature 1: | Japan Mitsubishi PLC |

| Feature 2: | ABBA linear guide |

| Feature 3: | Double station |

| Mould clamping force: | 125KN |

| Clamping plate: | 800*600mm |

| Min mould clamping distance: | 150mm |

| Power of hydaulic station: | 4KW |

| Certification: | SGS,ISO9001:2008,CE |

| Weight: | 6200KG |

| Production Capacity: | 150 Sets Per Year |

| Packing: | Bubble film then into the wooden case |

| Delivery Date: | 45 days upon receipt of deposit |

Product Description

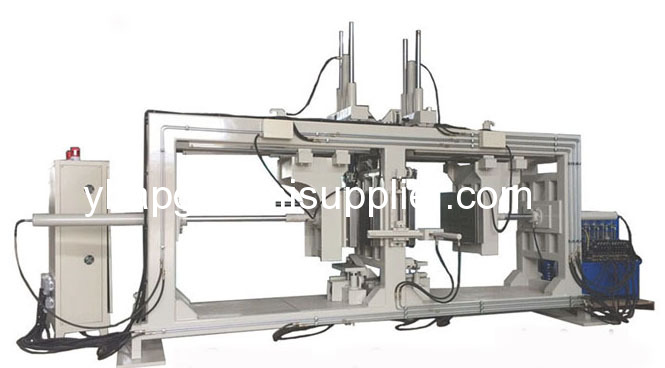

APG clamping Epoxy-resin automatic pressure transformer apg injection moulding machine

Product Overview

APG-858 It adopts structure of fixed mould plate in the middle, one set of equipment

can be used as two, when one side carries out clamping and injection production, the other side can be opened to take out the product, and clean the mould, it not only cuts down the equipment cost, but also improves the production efficiency. It has upper and lower core pulling, is suitable for small-sized bushing, contact box, post insulator, sensor,

various supports, transformer, etc.

Main Technical Diameter

Item | Technical Parameters |

Product Name | APG automatic clamping machine |

Model | APG-858 |

Clamping plate | 800*600mm |

Mould clamping force | 125KN |

Mould clamping speed | 3.2m/min |

Max mould clamping distance | 1000mm |

Min mould clamping distance | 250mm |

Power of hydraulic station | 5.5KW |

Heating power | 24KW |

Inclination angle of complete machine | Horizontal 0~5℃ |

Weight of complete machine | 6200KG |

Outline dimension | 5400*1200*3020mm |

Feature

APG equipment is made of main engine, hydraulic station,power

distribution and mixing device. It applicable for transformer, insulators, contact boxes and other epoxy resin casting products.

The products looks smooth, without bubbles. Meet different requirements well.

● Easy operation,only need 1-2 workers operate the machine

● The molds can be used frequently,shorten the curing time

● Good product quality,fine surface finish of products without air bubbles

● Chemical resistance,electrical insulation,strength resistance greatly improved

23 years experience, Engineers are available to service overseas for installing, debugging and technical training

Our advantage

YIBO VS Other Suppliers | ||

Items | YIBO | Other Suppliers |

Set the machine start time | √ | × |

Offer electronic vacuum gauge | √ | × |

Offer thin film de-gassing, excellent vacuumize | √ | × |

Offer oil cycling heating surround pot, heated evenly (For the vacuum stirring mixing device) | √ | × |

Pressure setting and safety valve improve safety coefficient (Double insurance for the vacuum stirring mixing device) | √ | × |

Offer matched APG mold | √ | × |

Offer free APG technique training | √ | × |

Steps of Quality Control

1.Strictly control the purchase standard of raw materials.

2.With high precision equipment and rich experience workers to process components, make each process up to standard.

3.Assembly process, recheck the quality of the components, the machine appearance etc.

4.Before shipment, test all operating procedures by winding the core to ensure the machine work normally.

Company information

1.The only manufacturer who can supply one-stop complete solution service for electric

industry of resin products such as CT,PT,insulators,SF6 shell.with best factory price and fast shipment.

2.Professional rich experience engineers and research team, we offer free APG technique training.Our engineers have 23 years experience who serviced many years in ABB.

3.100% promise to teach APG technique to you even you are newcomer.

4.Have a line and lab special for producing CT and PT.we can winding samples and test in our lab.

Contact Information

Website:www.ybapg.com

Tel | What's App | Wechat:+86 188 24102415

Email | Skype:laura(at)ybapg.com