Wire mesh belt shot blasting machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Shot Blast Machine, Shot Blasting Machine |

Product Detail

| Model No.: | QWD |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Others |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Others |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Others |

| Brand Name: | Hesong |

| Production Capacity: | 300 |

| Packing: | standard packing |

| Delivery Date: | 30 days |

Product Description

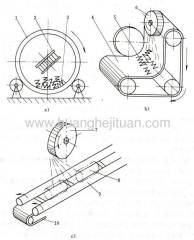

Wire Mesh Belt type continuous production shot blasting machine are designed to offer high production cleaning of various parts and castings. They provide a cost effective solution for batch cleaning, deburring, descaling, decoring and peening a wide variety of products.

Equipment: Wire Mesh Belt Conveyor, blasting chamber, blast wheel, abrasive recycle system, separator , dust collector, digital control panel etc.

Design and Sequence of Operations

Parts placed on the wire mesh belt conveyor continuously pass through abrasive tight entry vestibule into the blast chamber.

The quantity and placement of the blast wheels coupled with the blast wheel horsepower determine the cleaning capacity and production capabilities of the machine. Blast wheels ensure complete coverage and cleaning of every angle.

The parts are blast cleaned passing through the blast chamber and then exit through the series of seals in the egress vestibule.

Wire mesh belt shot blasting machine is mainly used for automobile, aerospace railway and other machine manufacturing industry, especially suitable for the surface of the thin-walled iron castings or aluminium castings and other small parts. It can be used for mechanical parts shot blasting strengthen.

The net belt shot blasting machine will deliver the workpieces to closed blasting chamber by a net conveyor system, it uses high-speed rotating blast wheel impeller to make shots blasting on surface of workpieces, so that to reach cleaning result. It is one kind of shot blasting equipment to disc shape castings, forging, structure and so on.

1.net belt structure, net be;t processing speed is frequency control, more uniform shot blasting, higher cleaning effect

2.steel net belt, slag skin is easy to leak, heat radiation of workpiece is goof, which can achieve effective cleaning of high-temperature workpieces

3.shots material circulation purification system adopts overflow controllable full multi-grade curtain winnowing separator and special polyester core line elevator belt to achieve separation and recycling of shots .

4.blasting chamber equips with multi-layer sealing curtain which can meet requirement of different workpieces. Shot blasting dust removal system uses impulse back flushing cartridge dust collector, dust removal result is good and service life is prolonged.

Net blet shot blasting machine is mainly used for automobile, aerospace railway and other machine manufacturing industry, especially suitable for the surface of the thin-walled iron castings or aluminum castings and other small parts. It can be used for mechanical parts shot blasting strengthen.

1. Steel Wire Mesh Wheel Continuous Shot Blaster is excellent for all-round, complete and continuous blasting treatment of flat as well as voluminous and very complex components.

2. With 4 or 8 high power blast wheels, mounted around the housing (both vertically and horizontally inclined), it is also possible to treat very complex components, which have "pockets" or difficult to reach areas.

3. A highly wear-resistant wire mesh belt, with tension adjustment, provides the part transport.

4. The special belt guiding enables the lower turbines to blast only through one belt position, which means that any masking is kept to a minimum.

Wire Mesh Belt Type Blasting Machine Uses

· Deflashing

· Descaling

· Profiling

· Surface Finishing

Model | QWD60 | QWD80 | QWD100 | QWD120 |

Belt width | 600mm | 800mm | 1000mm | 1200mm |

Blasting speed | 0.5-4m/min | 0.5-4m/min | 0.5-4m/min | 0.5-4m/min |

Shot blasting capacity | 4x120kg/min | 4x120kg/min | 4x180kg/min | 4x250kg/min |