Plastic Injection Molding Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100 Set/Sets per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service, Other |

| Main Products: | BLOWING MOULD MACHINE, INJECTION MOLDING MACHINE |

Product Detail

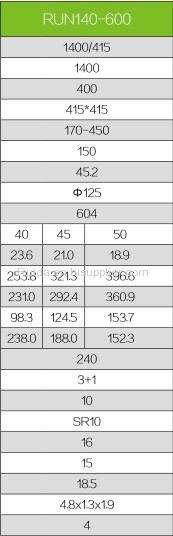

| Model No.: | RUN140 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | CHUANG HUI |

| Power: | 18.5kw |

| Min.Order Quantity: | 1 Set/Sets |

| Port: | Ningbo |

| Condition: | New |

| Type: | Preform Injection |

| Place of Origin: | Zhejiang,China (Mainland) |

| Injection Weight: | 231.0-360.9g |

| Model Number: | RUN140 |

| Packing: | Standard export packing |

| Production Capacity: | 100 Set/Sets per Month |

| Packing: | Standard export packing |

| Delivery Date: | 7days after getting the advance money |

Product Description

Standard technical data and machine connect interface;it fit all requirements of the global customers.

European designs standard, high quality and good price.

High efficiency energy designs and equipment.30-85%energy saving,and help customer to saving money.

parameter

Details

BASEMENT UNIT

Less welding oil defense constructions reduce the basement welding internal stress and improve the basement rigid.

Full closed and highly rigid welding basement ensure the moving precision of machine.

CABIN UNIT

Meet the safety requirements of the protective structure, unique arc

Modular structure of the cabin unit.

and diamond outlook design.

MECHANICAL UNIT

Double parallel injection cylinders system is stable construction and supplying high injection pressure.

Specialized material feeding hole ,material fall down smoothly.

No block barrel cooling system,improving the life of the injection cylinder seal.

Optimized five points toggle clamping cinstruction,movement of the IMM will be more smoothly.

The layout of toggle system is our patent, clamping unit have prefect system strength, and less maintenance cost.

The precise volume lubrication system extends the life pf the machine ,and keeps the machine clean for longtime.

CONTROL UNIT

Standardized electrical circuit and using of well-known components ensure the stability and reliablity of the control unit.

Energy saving servo system and controller system create the max value for the customers.

HYDRAULIC UNIT

Energy saving power system reduces the cost of electric power and water resource.

Separately hydraulic block provided easy maintenance and inspection,less energy losing of hydraulic system.

Accoering to safety hydraulic circuit assure the operator safe.

Clamping hydraulic circuit improves the machine running efficiency and stable.

Stable back pressure improves the precision of the molding component.

Our Services

1) Quality & Service : We take care of the product quality in order to provide good service to our customers.

2) Price : In order to serve more better to our customer we are always finding the way to reduce the price.

3) After one year , we can help you to maintain the machine and the accessories are provided only one the cost price.

4) Free production technology and process configuration.

5) We can help you to design the product line , workshop and provide turn-key project.

Contact Us

• We highly appreciate your any enquiry by email, fax or instant message.

• We will reply your email or fax within 24 hours.

• Please feel free to call us at any time if there is any questions.