Nordberg HP cone crusher parts

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 10000 Pcs per month |

| Place of Origin: | Shanxi |

Company Profile

| Location: | Taiyuan, Shanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Crusher Parts, Crusher Wear Parts, Crusher Spare Parts |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Coal |

| Type: | Crusher |

| Brand Name: | SIMIS |

| Certificate: | ISO9001 |

| Production Capacity: | 10000 Pcs per month |

| Packing: | Export Standard Packing |

| Delivery Date: | 30 Days |

Product Description

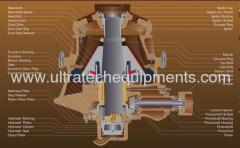

Nordberg HP cone crushers are high Performance for higher Profitability cone crusher. They are built on the success of 70+ years of Symons cone experience, and 20+ years of Nordberg Omnicone experience. The Symons cone is well known for its rugged construction and application versatility. The Symons cone has set the standard in the mining industry, where 24-hour, highreduction applications can destroy all but the most ruggedly built machine. The Nordberg Omnicone introduced many new innovations to reduce maintenance and operating costs, and to provide designed-in modern features such as hydraulic setting adjustment, tramp release, and cavity clearing. The field-proven HP series combines the best of these technologies to provide the highest capacity, the best product shape, the highest on-spec yield, easy automation, and the greatest possible reliability and flexibility. All to help you achieve the highest possible levels of profitability.

We use centrifugal casting and sand casting machines manufacture the HP series cone crusher bronze bushing. The material is standard C93700(GZ-CuPb10Sn DIN 1716) and C93800(SAE 67). The HP series cone crusher machines bronze parts is complexer than Symons bronze parts. We have the advanced CNC lathe to machine them. These parts are defect free with smooth surface. So our parts can supply long working life and reduce your replace cost, use cost and purchase cost. The prices are competitive too. And we can supply the customized parts to fit or repair your machines with your drawings.

We use resin sand casting to manufacture the manganese steel parts for HP series cone crusher. The material is Mn18Cr2. Our manganese steel parts follow a strict process flow, including casting, heat treatment and machining. So we can supply the long working life manganese steel mantle, bowl liner and jaw crusher's liner, especially hard ore processing.

We have advanced CNC ring rolling machines and sand casting machines to manufacture the steel bushing, Gear and Main shaft for HP series cone crusher. The max weight of single forging parts is 4 tons. All of our steel parts are past flaw detection, heat treatment, quenched and tempered for keeping high quality and mechanical properties.