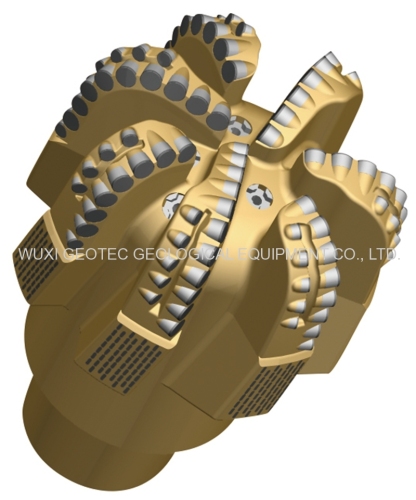

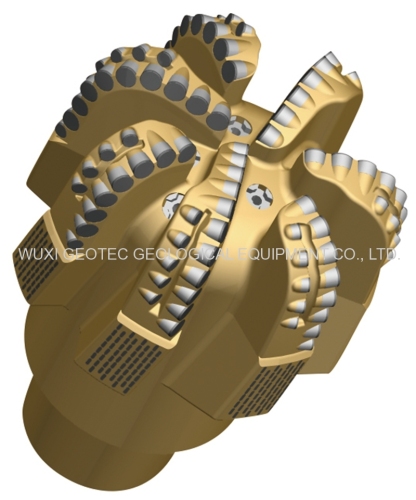

1, Flat Face PDC Non-coring Bits (Newest Design)

Description:

This kind of diamond tool has good performance for various rock

formations, and it is mainly used for general drilling. The powdered

metal matrix ensures strong abrasion resistance and long service life.

Advanced geometric design is adopted for fast penetration.

2, PDC Face Discharged Coring Bits

Description:

With the advantages of good cutting fast penetration, fluent water

passing, high efficiency in getting core and long bit life, our PDC face

discharged coring bits are applied soft to medium hard rock formation.

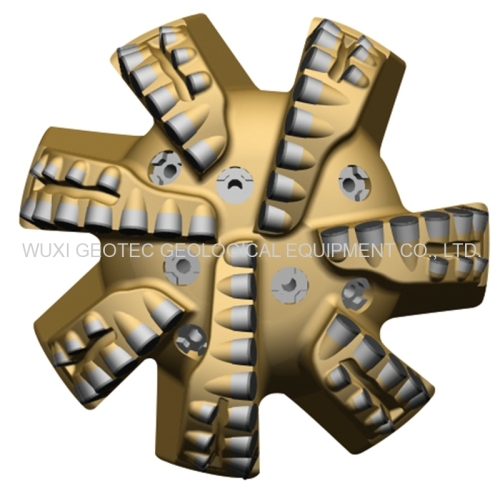

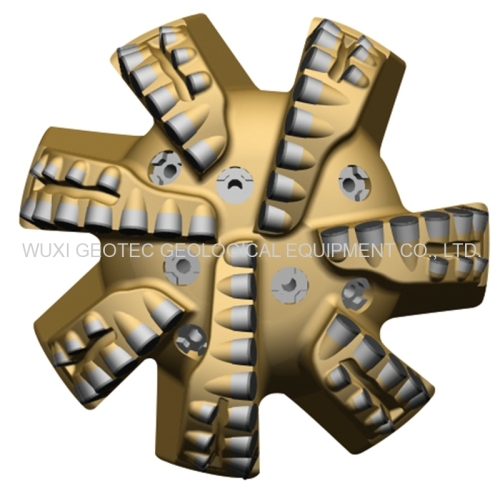

3, Multi-Blade PDC Non-coring Bits

Description:

Multi-blade PDC non-coring bit is designed for opening holes. Standard

PDC cutters are distributed on the blades. Balance design is used to

improve the stability and efficiency of drilling. It has the advantages

of fast penetration and high drill efficiency in soft rock.

4, Round Profile PDC Non-coring Bits

Description:

This product only has small interface with the rock. Column diamond is

used to protect inner and outer gauge, in addition, extra PDC cutters

are used to enhance gauge protection. The bit can be cleaned and cooled

sufficiently due to the design of flow roomage. This product is widely

applied to soft to medium hard rock formation.

5, Three (Four) Wings Round Profile PDC Bits

Description:

Our round profile PDC bits are improved according to oil bits. High

performance PDC cutters adopted can highly decreases the cutting

resistance and maintains a long service life. This type bits have faster

penetration, longer life and stronger adaptability than conventional

concave multi-wing bits. It is widely applied to medium soft rock

formation.

6, 3 Blades PDC Bits

Description:

This product is a new design type blade bit. It has three blades and

capacious flume. 3 blades PDC bits enjoy the features of high drilling

efficiency and fast penetration. The capacious flume ensures that water

can pass through it quite fluently. They are applied to medium hard rock

formation.

7, PDC Reamer Bits

Description: PDC

Reamer bit is applied to reaming and drilling in medium hard rock. With

the features of good guidance capability, sharpness, stable use and

abrasion resistance, our PDC reamer bits are widely applied in medium

hard rock.

8, Three Wings Concave PDC Non-coring Bits

Description: The

stability and efficiency of drilling are largely improved owing to the

balance design of cutters. Flow roomage is specially designed so that

bit can be clean and cooled sufficiently. This type PDC bit enjoys the

features of good stability and universality. It is applied to soft to

hard rock formation.

9, PDC oil coring set bit

Description: With the features of stability and high performance, this product is specially applied to oil drilling.

10, Normal complete-pieces PDC Bits

Description:

This product is widely applied to soft to hard rock formation. It

adopts the wearproof material which maintains a long service life of

drill. specifications:25mm 28mm,30mm,32mm,36mm,42mm.

PDC bit is developed in a significant advanced technology of diamond

drilling. The disc shaped polycrystalline diamond pads, or cutters, are

set strategically in rows on the bit face. These cutters consist of a

layer of polycrystalline diamond on a tungsten carbide substrate and it

allows the bits to drill through formations which are too soft or too

sticky for conventional diamond drill bits. The PDC bits are designed

for vertical, slant or horizontal drilling and can be used for either

non core, side track or recovery purposes.

4.1/2", 4.3/4", 5.1/8", 5.5/8", 5.7/8", 6.1/4", 6.3/4", 6.5/8" 7.3/8" etc. PCD bits are avaiable.