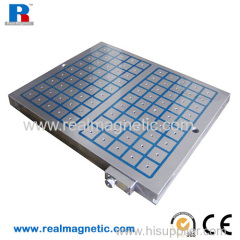

D600 Electro permanent magnetic chuck for lathe machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,DDP,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Magnetic Lifter, Permanent Magnetic Chuck, Electro Permanent Magnetic Chuck |

Product Detail

| Model No.: | EPQ |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Processing: | Milling Machine |

| Workpiece and Weight: | Large Machine Tool |

| Precision: | High Precision |

| Controlling Mode: | CNC |

| Usage: | Others |

| Brand Name: | Realmagnetic |

| Pole size: | 75*75mm |

| pole number: | 24 |

| Diameter: | 600mm |

| Holding force: | 750 KGS |

| Production Capacity: | 100 sets per month |

| Packing: | Plywood |

| Delivery Date: | 15~20 days |

Product Description

Electro permanent magnetic chuck is a new clamping tool for cnc machine and milling machine. 5-side processing is available for EP chuck.

® DESCRIPTION

1. Application

For milling and grinding processes.

Best suited for workpieces at least 250x250mm and 10mm thick, also with limited thickness and normal operating air gaps.

2. Features

Pole size:75 ×75mm

850kgf for each pole

High poles density

Magnetic field depth:10mm

2. Advantages

More convenient and high efficiency

5-sided machining is possible in one clamp

Energy saving, no electric power supply during clamping

Very Easy and quick to set up, no modification to the machine and line

Workpieces larger than table surface are machinable

Constant and concentrated force during clamping

Reduced consumption of tools

Improved finishing and greater accuracies

Facilitated interaction with CAD/CAM system, simplified CNC or FMS programming

® PRODUCTS(electro permanent magnetic chucks)

REALPOWER MAGNETIC is a professional designer, manufacturer and trader in magnetic tools field since 2003, with its unique technology and many years experience.

Products include 3 main components as follows:

Electro-Permanent Magnetic Chucks

Permanent Magnetic Chucks

Lifting Magnets

All these products were widely used and popular in metal process, material handle, mould quick change system etc, .These tools will help you get much more efficiency, more precision, and will make you get much more benefit.