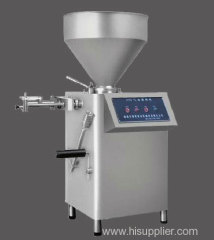

Vacuum Sausage Stuffer& Filler

| Trade Term: | FOB,CFR,CIF |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Meat Sausage Processing Machines |

Product Detail

| Means of Transport: | Ocean |

|---|

Product Description

Vacuum Sausage Stuffer& Filler ZKG3000,3500,4500,7500,9000

Description

Vacuum Sausage filler ZKG Series is always your first choice for continuous filling tasks. Most reliable vacuum sausage stuffer with rotary vane pumps appropriate for any-sized plants. Combine the Vacuum StufferZKG + Mech.Greatwall Double Clipper JCSK-A allows them to be perfect partner rapidly adapted to a wide variety of tasks in a sausage production plant.

Vacuum Sausage Stuffer machine ZKG is built with a combination of Japan YASKAWA servo motor and Italy BONFIGILION (German) decelerator as its drive system, also featuring its man-machine interface from Taiwan, Japan Mitsubishi PLC and Germany Busch vacuum pump. Key parts produced by machine center with high precision. All of pump, impeller and blade have are adopted the special heat treatment technique, highly smooth surface, easily to be cleaned up.

Model

Model | Quantitative Range (g) | Power (kw) | Stuffing And Kinking Speed (Times/Min.) | Quantitative Deviation (minced meat) (g) | Hopper Volume (L) | Voltage (v) | Weight (Kg) | Size (mm) |

ZKG-3000 | 6-9999 | 7.9 | 0-600 | ±2 | 160 | 380 | 590 | 1350x861x1710 |

ZKG-3500 | 6-9999 | 8.35 | 0-600 | ±2 | 240 | 380 | 630 | 2450x1180x1800 |

ZKG-5000 | 6-9999 | 9.2 | 0-600 | ±2 | 240 | 380 | 750 | 2450x1180x1800 |

ZKG-7500 | 6-9999 | 10 | 0-600 | ±2 | 240 | 380 | 830 | 2450x1180x1800 |

Application

Application: Natural casing ,collagen casing and smoke casing twisting.

Dual filling tubes and vacuum filler ZKG can be combined with full-automatic clipper machine.

Twisting speed: 640pcs/min(e.g 6g/pc)(stepless speed regulating available)

Twisting tube size: Φ10 Φ12 Φ14 Φ16 Φ19 Φ22(optional 3)

Clipping and filling tube: Φ16 Φ22 Φ28 Φ30 Φ40(optional 3)

The favorable inclination of the hopper walls facilitates day-to-day work, as the Lifter unit pumps the hopper completely empty apart from minimal residues. For automatic feeding, the ZKG series can be optional fitted with a lifting and tipping device which the operator controls using the relevant keys next to the portioning computer.

Vacuum Sausage Filling Machine Advantages:

Equipped with automatic casing knot tying device.

Suits straight-filling artificial, collagen, cellulose or linking natural casings.

High weight accuracy, effective production output.

Systematically with the clipper of various types, enjoy the benefit of automation production for your business.

Easy to clean using standard cleaning equipment.

Removable covers on two sides of the machine make the inside of the machine easily accessible for any maintenance work.

Maintenance work is automatically displayed on screen as it falls due.