PVD Vacuum Coating Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,CIP,CPT,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | Customized |

| Place of Origin: | Hunan |

Company Profile

| Location: | Xiangtan, Hunan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Vacuum Coating Machine, ITO Glass Sputtering Line, Magnetron Sputtering Machine, PVD Coater, Cutting Tools PVD Coater |

Product Detail

| Model No.: | EV-1200 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Equipment Name: | PVD vacuum coating |

| Origin: | China |

| Type of coating: | Vacuum coating |

| Raw material: | Aluminum |

| Samples: | Yes |

| Color of machine: | Custmized |

| Production Capacity: | Customized |

| Packing: | Standard Export Packing |

| Delivery Date: | 60 days after order |

Product Description

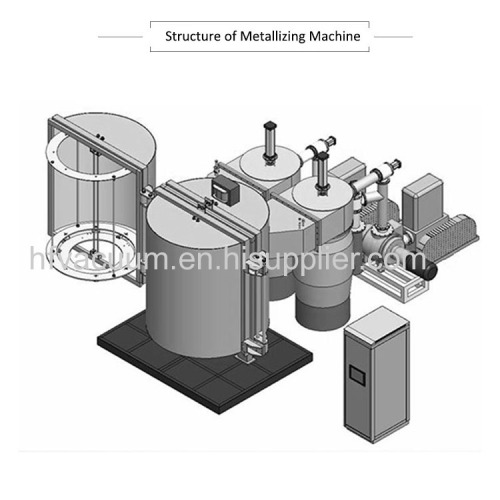

PVD Vacuum Coating Machine

[We provide technical troubleshooting service and modification solution for old machines]

Physical Vapor Deposition (PVD) – an environmentally friendly method of deposition of thin films, coating a substrate with a vaporized form of desired material.

Magnetron Sputtering – Atoms or ions are electrically ejected from a "target" and transferred to a substrate within a vacuum chamber

Cathodic Arc Deposition – material is vaporized from a cathode target and deposited to a substrate, through use of an electric arc.

Evaporation Deposition – material is evaporated and deposited to a substrate within a vacuum chamber.

Advantages of this machine(vacuum PVD coater):

1) Simple visual interface for the operator, process control system runs on Windows system interface and easy to use

2) Vacuum pump system efficiency, which increases productivity due to shorter batch times

3) High performance layer monitoring system is equipped for enhanced production result

4) Automated work cycle, which requires less workers per shift and training time, low production cost

5) Repeatable and reliable coating

6) Safter and Environmentally-friendly process guarantee

7) Highest yield

• Fully automated work cycles

• Rapid cycles for high productivity

• Removable shielding for easy maintenance

• Quick change fixturing

Coating properties:

• Excellent layer properties

• Longer lifetime

• Smooth surface

• Many bright, metallic colours, decorative or functional

• Excellent scratch protection