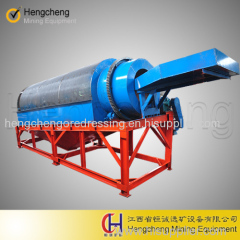

ore beneficiation machine gold wash plant trommel screen for sale

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 100sets per month |

| Place of Origin: | Jiangxi |

Company Profile

| Location: | Ganzhou, Jiangxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Mobile Gold Mining Equipment..., Rotary Scrubber, Spiral Chute, Jig Cncentrator, Trommel Screen |

Product Detail

| Model No.: | GT |

|---|---|

| Means of Transport: | Ocean |

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Hengcheng |

| machine type: | gold wash plant |

| Trommel length:: | 1000-5000mm |

| Feed size::: | <200mm |

| Mesh Size:: | <3~10mm |

| Dimension(L*W*H): | 5960*1900*3080mm |

| Weight:: | 2200-7500kgs |

| Spare parts:: | supply |

| Operation:: | under guidance |

| Production flowchart design:: | supply |

| Whole plant layout design:: | supply |

| Production Capacity: | 100sets per month |

| Packing: | export standard container |

| Delivery Date: | within 20-30 working days |

Product Description

ore beneficiation machine gold wash plant trommel screen for sale

Description of gold tromme screen:

Trommel machine is a very important screening & separation equipment in alluvial deposit processing projects, it provides a simple,efficient and economical solution to upgrade a wide rang of material, and optimize the subsequent process steps of recovery. This method of screening helps not only to reduce manual operation and investment, also increase product grade, while allows rapid and large volume processing.

Features of mining machinery gold trommel screen.

· Configured for economical & efficient classification, Screening and grading

· Heavy duty trommel drum with lifters at the front to facilitate material break up

· Screen replaceable for different mesh sizes

· Multiple screen size

· Easily changed screen plates

Advantages of mining machinery gold trommel screen.

The gold drum screen provides a simple, efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing. Trommel screens are constructed of high quality material, designed for high performance, high production rates, loweroperating costs and lower maintenance. This material is then passed on to the downstream process equipment which can be in various forms such as centrifugal Concentrator, spirals, jigs etc.

Technical specification: gold trommel screen.

Model | Capacity (t/h) | Power (kw) | Drum Diameter (mm) | Drum Length (mm) | Screen Size (mm) | Dimension (mm) | Weight (kg) |

GT1015 | 10 | 4.0 | 1000 | 1500 |

<3~10 | 3000*1400*2145 | 2200 |

GT1020 | 20 | 5.0 | 1000 | 2000 | 3460*1400*2145 | 2800 | |

GT1225 | 35 | 7.5 | 1200 | 2500 | 4146*1600*2680 | 4200 | |

GT1530 | 50 | 11 | 1200 | 3000 | 4460*1900*2820 | 5100 | |

GT1545 | 70-125 | 15 | 1500 | 4500 | 5960*1900*3080 | 6000 | |

GT1845/1850 | 90-150 | 22 | 1800 | 4800/5000 | 6500*2300*4000 | 7500 | |

GT2055 | 120-180 | 30 | 2000 | 5500 | 7500*2500*4000 | 8600 |

Company information:

Jiangxi Hengcheng Mining Equipment Company is specialized in manufacturing various kinds of mining equipment. We have served the mineral processing industry as an excellent mineral processing equipment manufacturer for over 20 years.

Hengcheng company is dedicated to provide a complete line of equipment including shaking table, spiral chute, jig machine ,trommel,rotary scrubber, flotation machine, magnetic separator ,grinding mill, and so on. We are involved in the range of mineral beneficiation services including mineral testing, process flowchart design, installation and commissioning, technical consulting, as well as staff training, etc. Our proven technologies and experience permit us to provide every customer with the most efficient & commercial beneficiation plant equipment.

Our service:

Jiangxi Hengcheng Mining Equipment Co.,Ltd is always going for the best quality and perfect service for customers

and it has already won lots of praises at home and abroad.

Pre-sales service:

Be a good consultant and assistant to customers, to ensure our customer's investment rewarded

with great profit.

1.Enough details about the ores or slags shall be learned, sometimes a test is needed for some ores.

2. Equipment of right model is selected for customers.

3. Customized products and processing flow sheet can be designed and developed to meet

customer's special needs,

4. Engineer could be sent to observe customer's working site to come up with an optimized solution

accordingly.

On-sales service:

Every customer is respected and convenience and reliability will be provided. We are devoted to

helping you to benefit as much as possible.

1. Inspection is a must before delivering of the goods.

2. Assistance to make a construction plan by supplying all drawings and data needed.

3. Most favorable scheme for you with the guaranteed quality.

4. Timely communication to make sure improvement of project and your requirement met.

After-sales service:

1. Installation, adjustment, and testing of equipment is available.

2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation &

adjustment is finished.

4.If any failure or question about the machines or the processing line, contact us and we are available

at any time.