Cr39 Optical Evaporation Coater Optical Vacuum Coating Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 15 sets per month |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | ZZS1120 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Guotai |

| Categories: | OPTICAL LENS COATING MACHINE |

| Coating Technology: | ELECTRON GUN , ION SOURCE |

| Coating Application: | CAR MIRROR, OPTICAL LENS, SPECTACLE, COLD LIGHT LAMP, DECORATIVE LIGHTING, RHINESTONE |

| Substrate temperature: | CONTROLLABLE AND ADJUSTABLE FROM ROOM TEMPERATURE TO 350°C (PID TEMPERATURE CONTROL) |

| Coating Features: | WELL UNIFORMITY OF FILM THICKNESS, WELL REPEATABILITY OF DEPOSITION, E-BEAM GUN, STABLE POWER OUTPUT, SMALL AND UNIFORM |

| Operation: | auto/manually/ self-auto/ with touch screen + PLC system |

| Business type: | China manufacturer/supplier |

| Warranty: | One year warranty, life-long maintenance |

| After-sales Service: | Engineers availableto service machinery overseas |

| Production time: | 2 months |

| Production Capacity: | 15 sets per month |

| Packing: | wooden case |

| Delivery Date: | 2 months |

Product Description

Cr39 Optical Evaporation Coater Optical Vacuum Coating Machine

This equipment is designed for coating precision optical thin film,each system unit and overall structure well meet the optical thin film production process requirements,which suitable for coating anti-reflection film, bandpass film ,IR-Cut filter etc.It equipped with high-precision film thickness control system,excellent performance electron gun,high degree automation coating control system, etc. It's the ideal equipment for coating high precision optical thin film.

Equipment technical indicators:

1.Chamber structure:cabinet vertical front opening door.

Vacuum chamber size:φ1120mm×H1300mm.

2.No-load limit vacuum:3×10-4Pa.

3.Pumping time:to 4×10-3Pa ,time ≤12min(no-load);

4.Coating process temperature:Indoor temperature to 350℃ adjustable.

5.Electron gun: 2pcs 270 degree,E-beam gun, Power: 8 kw adjustable.

6. Crucible:2sets,one set crucible with 12holes(right),40CC/hole.

7.Resistance evaporation source: single power supply 5 kw,evaporation current 500 A.

8.Substrate holder speed 3~30rpm

9.Cryogenic system

10.Hall ion source.

11.Film thickness control instrument:American Inficon SQC-310 Quartz crystal single probe control system.

12.Vacuum system control:15 inches touch screen + PLC,Manu/Auto control ,which can realize continuous automatic coating.

Acceptance Process:After machine making ,Seller will inform buyer to come to factory to check, at that time it can be testing for coating sample ,in user factory as the final checking. Seller must install ,testing on time and on the quality .After the whole machine be installed ,tested ,please buyer depend on the technology agreement and acceptance criteria.

What we will do ?

1.Installation: The supplier should send engineers to buyer's factory and help installation, commissioning and support of the production process. The round tickets, room and food should be to be paid by buyer. The buyer should assist and cooperate when needed.

2.Traning:during installation ,operator and maintenance man must full participate .supplier will provide traning in the locale including daily operation ,maintenance ,operation problem analyze and process of urgency.

3.After sale service: One year guarantee ,it will offer the best service in the guarantee or past guarantee .Due to improper use, or other damage to the equipment not itself no warranty, wearing parts is no in the repair. Guarantee begin to the machine finish testing .

Company introduction:

Chengdu Guotai Vacuum Equipment Co.,Ltd is a large vacuum coating equipment company ,which is collection of research & development ,production,marketing,and after-sales service of integrated.

We are focus on manufacturing Optical Vacuum Coating Equipment,Winding Vacuum Coating Equipment,Continuous Coating Production Line,Magnetron Sputtering Vacuum Coating Machine,Vacuum Electric,Vacuum Parts and Consumables etc.Machine produces film which widely used in electro-optical system and thin film instruments,such as digital cameras,digital video,binoculars,projector,energy control,optical communication,display technology,interferometer,satellite missiles,semiconductor laser,mems,information industry,laser production,various kinds of filter,lighting industry,sensors,architectural glass,automotive industry,decoration,glass lens,metal,resin,ceramic,etc.Good quality products and excellent after-sales service make company market share increasing by 35% per year.Except sale equipment ,we also undertake a variety of optical coating services.

We adhere to honesty,quality first as spiritual idea,innovation,dedication,harmony and win-win as principle,provide high quality products and excellent service to each customers.Chengdu Guotai Welcome your come.

Workshop show

Our team

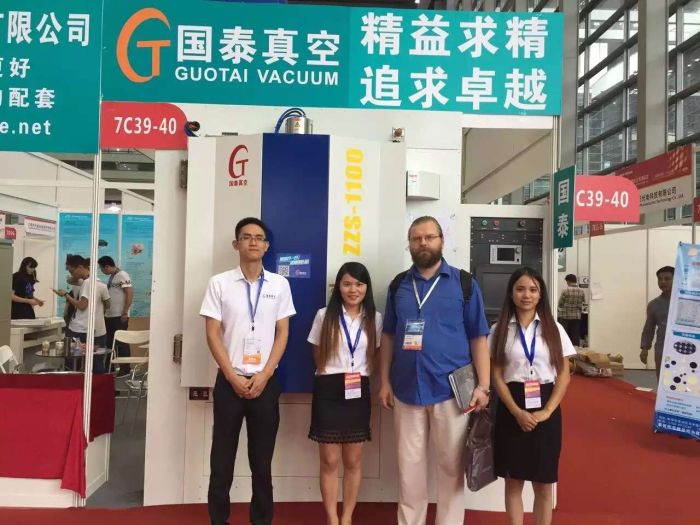

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements,we also undertake all kinds of optical coating film service.

What we can do more for you :

1.One year guarantee period ,life-long maintenance.During warranty period free replacement parts.

2.The whole electric control manufactured by us, including vacuum gauge and pressure control instrument,etc.Once there are problems,we will be free to provide them to you to replace ,make sure decrease your lose during equipment downtime.

3.Free training for operation and maintenance personnel,provide detailed equipment maintenance materials,include consumables parts number and contact way,to make sure customers can independently replace vacuumpump,regular system maintenance,when necessary.

4.If fault occurs during equipment use process,we will respond within 24 hours,If due to manufacturing reasons,we will bear responsibility.

5.We will keep long-term tracking ,when upgrading products we will provide cost price replacement , to make equipment achieve better performance,to realize our compromise of equipment further improve and perfect .

6.We can make relative adjustment according to your special requirements .