DC Magnetron Sputtering System Coating Machine For Coating Plastic Products

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 15 sets per month |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | ZCK-1200 Magnetron sputtering coating machine |

|---|---|

| Means of Transport: | Ocean |

| Type: | DC Magnetron sputtering coating machine |

| Substrate: | Titanium nitride magnetron sputtering coating machine |

| Coating: | Vacuum Coating |

| Warranty: | 1year warranty,lifetime maintenance |

| Technology: | Titanium sputtering plating machine |

| Control mode: | PLC control system,full automatic control |

| Coating film: | Copper, titanium, chrome, stainless steel, nickel etc |

| Coating material: | stainless steel, metal alloy, ceramic,glass etc |

| Model Number: | ZCK-1200,ZCK-1400,ZCK-1600,ZCK-1800 |

| Production Capacity: | 15 sets per month |

| Packing: | Wooden package |

| Delivery Date: | 2 months |

Product Description

DC Magnetron Sputtering System Coating Machine For Coating Plastic Products

Magnetron Sputtering System principles:Magnetron Sputtering is a Plasma Vapor Deposition (PVD) process in which a plasma is created and positively charged ions from the plasma are accelerated by an electrical field superimposed on the negatively charged electrode or "target". The positive ions are accelerated by potentials ranging from a few hundred to a few thousand electron volts and strike the negative electrode with sufficient force to dislodge and eject atoms from the target. These atoms will be ejected in a typical line-of-sight cosine distribution from the face of the target and will condense on surfaces that are placed in proximity to the magnetron sputtering cathode.

Introduction:

This series of equipment is mainly used DC or intermediate frequency magnetron sputtering, can adapt to extensive coating material, such as, copper, titanium, chrome, stainless steel, nickel and other metal materials.Using sputtering coating process can improve coating adhesion, repeatability, density, uniformity, etc.Magnetron sputtering coating equipment applied to plastic products, ceramic, resin, crystal glass products, artware, such as plastic mobile phone shell, electronic products, building materials and other industries.

Application:

Chengdu Guotai manufactures and supplies all kinds of PVD vacuum coating machines. Show me your products ,we will design a solution to meet your process requirements.

Company introduction:

Chengdu

Guotai Vacuum Equipment Co.,Ltd is a large vacuum coating equipment

company ,which is collection of research & development

,production,marketing,and after-sales service of integrated.

We

are focus on manufacturing Optical Vacuum Coating Equipment,Winding

Vacuum Coating Equipment,Continuous Coating Production Line,Magnetron

Sputtering Vacuum Coating Machine,Vacuum Electric,Vacuum Parts and

Consumables etc.Machine produces film which widely used in

electro-optical system and thin film instruments,such as digital

cameras,digital video,binoculars,projector,energy control,optical

communication,display technology,interferometer,satellite

missiles,semiconductor laser,mems,information industry,laser

production,various kinds of filter,lighting

industry,sensors,architectural glass,automotive

industry,decoration,glass lens,metal,resin,ceramic,etc.Good quality

products and excellent after-sales service make company market share

increasing by 35% per year.Except sale equipment ,we also undertake a

variety of optical coating services.

We adhere to honesty,quality

first as spiritual idea,innovation,dedication,harmony and win-win as

principle,provide high quality products and excellent service to each

customers.Chengdu Guotai Welcome your come.

Workshop show

Our team

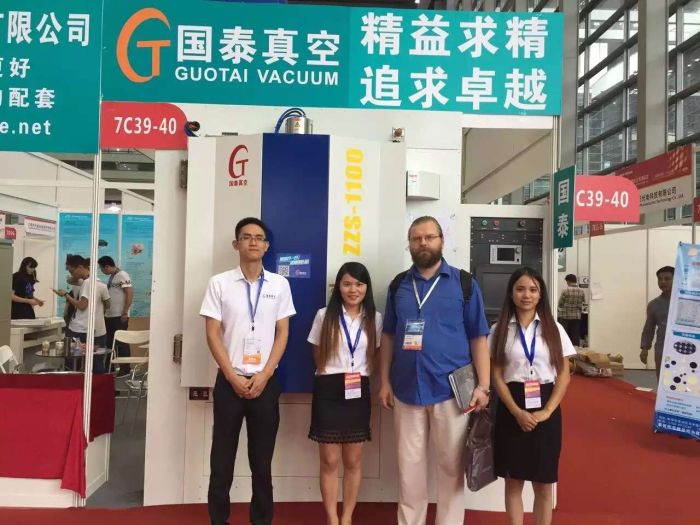

Customer visit

Exhibition

Certification

Package show:

Note:

1.We supply optical vacuum coating equipment,winding vacuum coating equipment,magnetron sputtering vacuum coating equipment,horizontal light coating equipment,continuous coating production line.

2.The final configuration customized production according to your process requirements.