plate hydraulic shearing machine motorized shear hydraulic cutting and bending machine shearing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000sets/per year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | BENDING MACHINE, CUTTING MACHINE, High Quality Hydraulic Press Brake, High Quality Press Brake Machine, NC Hydraulic Press Brake With E21 |

Product Detail

| Model No.: | QC12K-8×2500 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Steel Bar |

| Machine Type: | Others |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | ZYMT |

| Standard Equipped Controller System: | E21S |

| Backgauge Travel: | 600mm |

| Controller with moveable arm: | Yes |

| Front and back protection fence: | Yes |

| Backgauge with ball screw: | Yes |

| Shadow line lighting: | Yes |

| Emergency Button: | Yes |

| Production Capacity: | 3000sets/per year |

| Packing: | plastic cover |

| Delivery Date: | 20 days |

Product Description

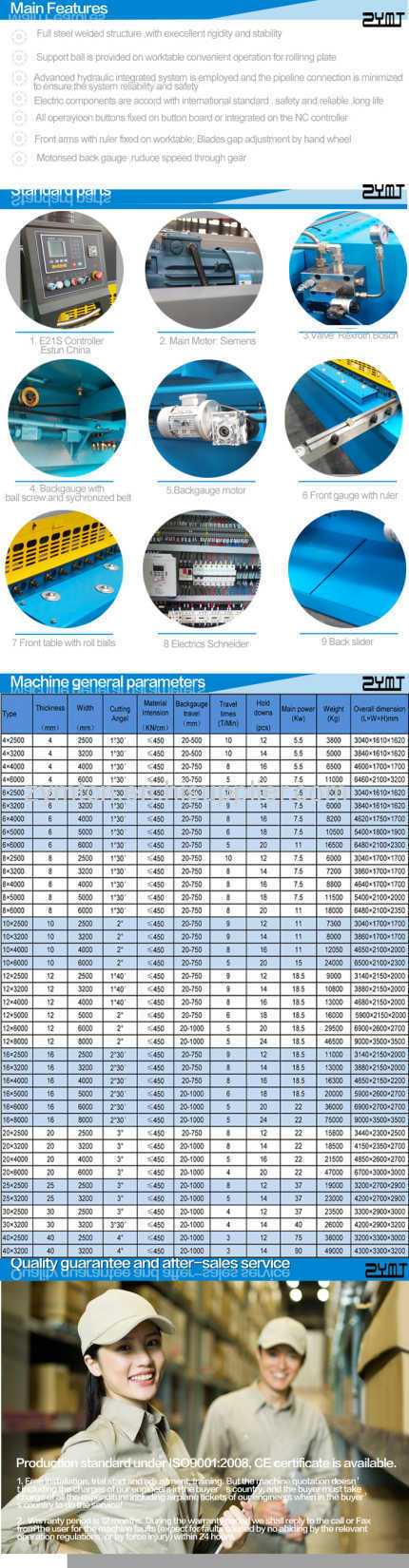

QC12Y Features

The machine is metal plate welded structure, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance, and nice appearance, fitted with digital controller.

Indication by indicator is provided for adjustment of blades clearance, for a handy and prompt adjustment.

Alignment device with lighting and control device for shearing stroke are set.

Worktable with balls for material feeding convenient, to minimize fish tail with sheet bar and to reduce frictional resistance.

QC 12K Features

The machine is fitted with CNC controller special for shearing machines.

The position of rear stopper is displayed in real-time manner.

Multi-step programming function is available and the rear stopper is able for automatic operation and continuous positioning, to achieve an automatic adjustment for position of rear stopper.

It is provided with counting function for shearing, to display the shearing numbers in a real-time manner, able for power-failure memory of position of rear stopper, procedures, and parameters.

Backgauge with precision ball screw and linear guide, to ensure the positioning precision, so that bring the higher precision prcsessing.

CNC Controller System

DAC310

Bright LCD 128×64 display

Backguage control, Gap control, Stroke length limitation.

Actual and programmed position visualization, Stock counter,

Programmable up to 100 steps.

Panel-based housing;

Servo control/unipolar/AC two-speed control;

mm/inch transmission;

E200S

Backguage control, bus mode control servo system;

Stroke length limitation, double pragrammable digital output;

Pragram memory of up to 40 program, up to 25 steps per program;

One side positioning, retract of function.

mm/inch transmission, Chinese/English transmission;

240×128 pixels LCD display.

E21S

Backguage control, control for general AC motor, frequency inverter;

Intelligent positioning, double programmable digital output;

Stock counter, program memory of up to 40 programs, up to 25 steps per program;

One side positioning, retract of function.

One key backup, restore of parameters;

mm/inch transmission, Chinese /English Transmission; LCD display;

P40

Analog or digital outputs for 1-3 speed operation 16 free programmable digital in-/outputs

Program memory(1000 sets)

Angle control/gap control/backguage

Limitation of the cutting length

Material List for angle and gap control

HT071

Regulated power supply for encoder or push pull/o.c.

optional line 12 Vdc±5% 120 mA

Optoisolated inputs

High luminosity led display having 6 digits plus sign for position,

2 digits fpr cycles and for programs.

Possibility to save up to 99 programs composed of 20 cycles.

Each cycle can count 65000 repetitions at maximum

Data and programs are saved in a flash memory without floating battery Ip 65, polycarbonate, water and abrasion-proof keyboard with tactile sensitivity.

China ESTUN E10S

X axis and Y axis position display;

Resolution:0.1mm or 0.0001 inch;

Stock counter, 2 timer integrated;

One side positioning indication;

Sofware limitation;

Power-off memorization.

Packaging & Shipping

(1)Before packing, the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied.

(2)Before loading, stable package, professional and skilled loader reduce damage of product during transport.

(3)After loading, our professional documentary staff will follow the order till the product departs from port.

Our Services

1. Shearing blades and accessories-Customized to your specifications. In our shearing blades, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases-even for complex technical ones.

2. Service package

Basic: we offer you rapid trouble shooting through telephone support and costs for on-site missions are reduced.

Special: Engineers available to service machinery overseas for the necessary maintenance.

Partner: Our located dealers or customers who sell or use our machines are fully behind you, they are our friendly partner and supply good advice to you.

3. Technical Service(After-sale service)

Installation and start-up(Available for complex and big machines or if you have demand)