Bending machine hydraulic bending machine hydraulic press brake cnc bending machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000sets/per year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | BENDING MACHINE, CUTTING MACHINE, High Quality Hydraulic Press Brake, High Quality Press Brake Machine, NC Hydraulic Press Brake With E21 |

Product Detail

| Model No.: | WC67K |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Steel Bar |

| Machine Type: | Press Brake |

| Extra Services: | Machining |

| Automation: | Automatic |

| Certification: | ISO 9001:2000 |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | ZYMT |

| Controller System: | E21 |

| Backgauge Travel: | 500MM |

| Emergency button: | YES |

| Front and back protection fence: | YES |

| Backgauge with ball screw: | YES |

| Production Capacity: | 3000sets/per year |

| Packing: | plastic cover |

| Delivery Date: | 20 days |

Product Description

Factory aerial view

Factory processing equipment  Company certificate  |

|

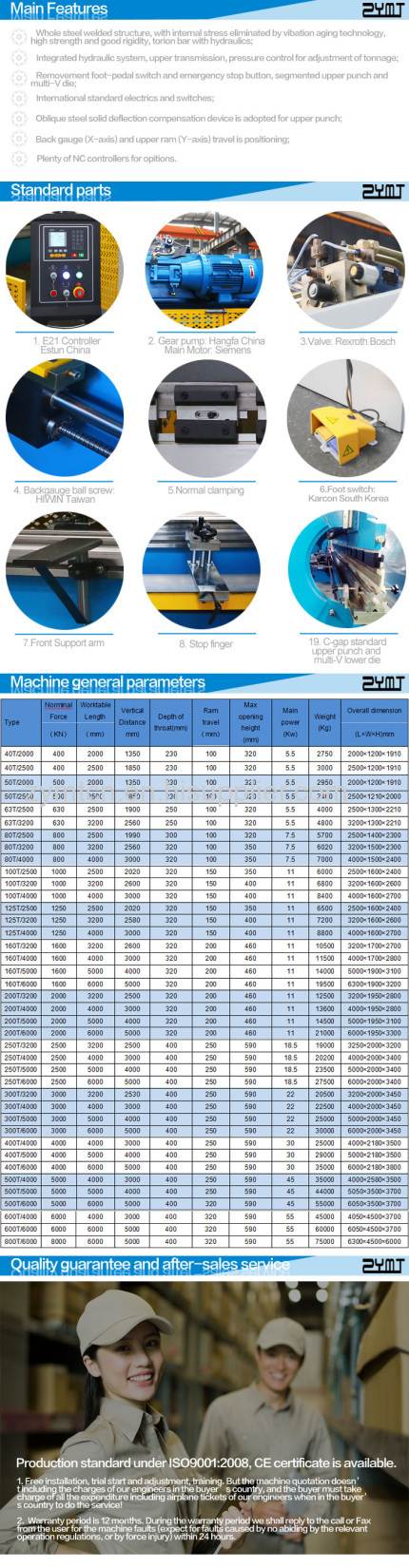

Features

WC67K:

WC67K series torsion bar NC control press brake which fitted with numerical controller basis on the WC67Y series brake.

Multi-steps programming function is able to achieve an automatic operation and continuous positioning of multi-steps procedures, as well as an automatic precision adjustment for position of rear stopper and upper beam.

The machine is provided with bend counting function, real-time display of processing quantity, power-failure memory of positions of rear stopper, upper beam,programs and parameters.

WC67Y:

The machine is metal plate welded structure, with internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

Double hydraulic oil cylinders are applied for upper transmission, provided with mechanical limit stopper and synchronize torsion bar, typical of stable and reliable operation, as well as high precision.

Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

Upper punch clamping fitted with deflection compensation device.

Packaging & Shipping

(1)Before packing, the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied.

(2)Before loading, stable package, professional and skilled loader reduce damage of product during transport.

(3)After loading, our professional documentary staff will follow the order till the product departs from port.

Our Services

1. Shearing blades and accessories-Customized to your specifications.In our shearing blades, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases-even for complex technical ones.

2. Service package

Basic: we offer you rapid trouble shooting through telephone support and costs for on-site missions are reduced.

Special: Engineers available to service machinery overseas for the necessary maintenance.

Partner: Our located dealers or customers who sell or use our machines are fully behind you, they are our friendly partner and supply good advice to you.

3. Technical Service(After-sale service)

Installation and start-up(Available for complex and big machines or if you have demand)