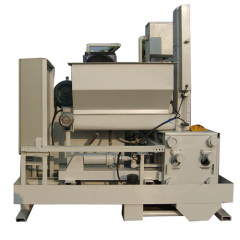

hydraulic metal scrap metal briquetting machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 15sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Hydraulic Metal Baler, Hydraulic Metal Briquetting Press, Hydraulic Metal Shear |

Product Detail

| Model No.: | Y83-2500 |

|---|---|

| Means of Transport: | Ocean |

| briquetting press: | hydraulic machine |

| Production Capacity: | 15sets/month |

| Packing: | depending on customer's requirement |

| Delivery Date: | 30 days after deposit |

Product Description

These precision engineered range of Hydraulic Metal Briqueting Machines are used in process of recycling Steel turnings, Cost iron bearing and Copper or brass powder. Efficiently handling demands of filling bulky ore in melting furnace, these are be chopped, shredded or broken with process involving double treatment where high pressure is exerted on small areas.

The machines offered by us allow in achieving superior process efficiency and achieving standard briquette sizes of 12 to 15 cms (diameter) & 10 cms (length). Increasing bottom-line profitability, these machines find usage in efficiently turning compact briquettes from:

Industrial turnings

Filings

Chips

Clippings

Metallic dust from copper, brass, aluminum and other metals

Cast iron

Aluminum

Copper

Magnesium

Titanium

Molybdenu

Parameter:

Nominal force 2500 KN 190 KN 245 KN 50 KN Cylinder inner diameter 320 mm 110 mm 125 mm 80 mm Piston rod diamter 200 mm 70 mm 70 mm 45 mm Work pressure 21 Mpa 20 Mpa 20 Mpa 10 Mpa Structure Four column vertical type Motor 22 KW Pump 80 MCY14-1B The briquette density ≥5 t/m³ Work efficiency 5 pcs/min (2-3.5 kg/pcs) Productivity 5-8 tons/shift (cast iron, 8 hours) The briquette diameter Φ80-100 mm Cooling system Water cooling/Air cooling Machine weight about 4 tons Control PLC Auto Size Machine 2100*650*2100 mm Oil container 1400*1400*700 mm