Medium frequency induction heating furnace

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 100 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GS-ZP-500 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Furnace |

| Processing Type: | Machining Equipment |

| Brand Name: | Lipai |

| Production Capacity: | 100 |

| Packing: | Wooden case |

| Delivery Date: | within 7 days |

Product Description

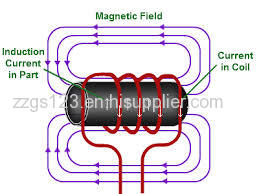

Working principle of medium frequency induction heating furnace:

Using circular induction coil, the need to deal with the metal work piece is placed within the induction coil, lead to high frequency alternating current (ac) had strong magnetic field generated in the coil, because the metal is internal resistance, so can produce a large number of joule heat, make the heating metal can quickly heat up, to achieve the effect of heat treatment. High frequency induction heating mow has been used more and more commonly for its speed, safety and environmental.

Features of medium frequency induction heating furnace:

1. The medium frequency induction heating furnace adopts IGBT modules (Siemens, Germany), high efficiency, and maximum energy saving.

2. Environmental features: Almost no oxide layer, produced no exhaust, no wastewater generated.

3. Heating fast: the minimum heating time can be 1~2 seconds.

4. Unique cooling circulation system, which will ensure the equipment can work for 24 hours continuously..

5. Easy installation and simple operation, few minutes only to learn.

6. Safe and reliable. no high voltage, no radiate, very safe for operating people.

7. Medium frequency induction heating furnace power can be adjust according to your request.

8. Accessories with machine: 2 pieces of induction coils, 1 piece of foot pedal, installing and operating instructions 1 piece

Parameters of medium frequency induction heating furnace:

| Model | GS-ZP-500 | Input Power | 500KW |

| Max Input Current | 750A | Working Voltage | 342-430V |

| Oscillation Frequency | 2-4KHZ | Cooling Water Pressure | 0.2-0.5Mpa |

| Host Size | 810*530*1780mm | Transformer Size | 500*800*580mm |

| Temperature Protection | 50℃ | Efficiency | 100% |

Applications of medium frequency induction heating furnace:

1. Heat treating

Work pieces surface heating treatment, parts surface hardening, annealing, etc. Such as gears, shafts, spline shaft, camshaft, hand tools, electric power tool, pipes, etc.

2. Hot forge

Forging, shaping, warm bending, high frequency shrinkage fitting, heat enveloping, metal desiccating, nut inserting, rotor inserting, etc. Such as heating sphere billet to remove inserts.

3. Induction brazing

Metal brazing, high-frequency brazing, pan bottom brazing, tool head brazing, copper brazing, induction soldering, etc. Such as diamond saw blades, carbide cutter, pick coal teeth, wooden tool, etc.

4. Induction annealing

Steel bar, copper wire annealing, stress relieving

5. Induction Melting

Precious metals melting, such as gold, silver, copper, zinc, etc.

6. Shrink fitting

Heating bearing to remove it from shaft, or heating drill bit, remove the inserts in it. Heat makes something expand and cold makes it contract

If you are interested in our equipment, please consult our website or contact us +86-15538376386

Email:li pai heating @ gmail.com

Skype:15538376386

Web: gslipai.com/

induction-heatings.com/