302/304/304L Stainless Steel Wire

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 200tons per day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Steel Grating;fence;Gabion Mesh |

Product Detail

| Model No.: | YC-W05 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | YACHAO |

| Production Capacity: | 200tons per day |

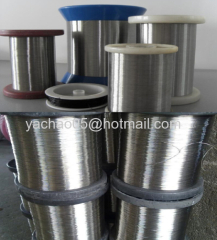

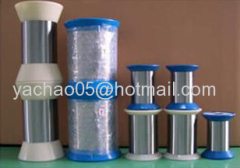

| Packing: | Waterproof paper, woven bag, plastic film outside in pallet, in bulk |

| Delivery Date: | 5-10 days after confirmation |

Product Description

Stainless Steel Wire

1,Material:201, 202, 304, 304L, 316, 316L,321, 310S, 430, 665 etc

Brand Name: YACHAO

Product no : YC-W05

HS Code:72230000

2,Surface treatment:bright, cloudy,plain

3,Min. order(MOQ): 100kgs

4,Supply ability:200tons per day

5,price range:1500-5000 per ton

6,Payment terms: L/C, TT,D/P,D/A, WESTEN UNION

7,Delivery time: 10-15days after confirmation

Product description

Stainless steel wire with stainless steel as raw material production of all kinds of different specifications and types of silk products, the origin of the United States, Japan, Holland, section is generally round or flat. Common corrosion resistance, high cost of stainless steel wire is 304 and 316 of stainless steel wire.

Feature

1.with good toughness and elasticity

2.Strong corrosion resistance

3.High quality low carbon steel

4.Direct Manufacturer

Manufacturing process

1. Rod 5.5mm → → drying coating film

2. Put on the pumping line → LZ8/600 Straight wire drawing machine drawing

(pulling to 1.8mm ~ 2.8mm) → SG740 spool winding (spring steel wire is not required)

3. mple pay-off protection ammonia decomposition furnace → → vertical take-down winding machine

4. Rod 1.8mm ~ 2.8mm → → drying → film coating placed on the pumping line →

LZ9/400 Straight wire drawing machine drawing (pulling to 0.8mm ~ 1.2mm) →

SG740 the word rolling wheel

Specification

1) Grade: 201,202,301,303,304,304L,305,316,316L,321,410,416,420,430...

1.4301, 1.4306, 1.4845, 1.4401, 1.4371, 1.4597,1.4541, etc

2) Standard: ASTM, EN,DIN,JIS

3) Diameter: 0.05-20mm

4) Surface: bright, cloudy, plain, black

5) Type: spring, welded, tig, mig etc

soft and hard

6) Packing: in coil or in spool then in carton or as your request

Type AISI | C Max % | Mn Max % | P Max% | S Max% | Si Max% | Cr% | Ni% | Mo% |

201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.000-18.00 | 0.5 | - |

202 | 0.15 | 7.50-10.00 | 0.06 | 0.03 | 1 | 17.00-19.00 | 3.-0-5.00 | - |

204CU | 0.08 | 6.5-8.5 | 0.06 | 0.03 | 2 | 16.0-17.0 | 1.5-3.0 | - |

302 | 0.15 | 2 | 0.045 | 0.03 | 1 | 17.00-19.00 | 8.00-10.00 | - |

302HQ/ | 0.03 | 2 | 0.045 | 0.02 | 1 | 17.00-19.00 | 9.00-10.00 | - |

304CU | ||||||||

304HC | 0.04 | 0.80-1.70 | 0.04 | 0.015 | 0.3-0.6 | 18-19 | 8.5-9.5 | - |

303 | 0.07 | 2 | 0.045 | 0.25 Min | 1 | 17-19 | 8.0-10.0 | 0.6 |

304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.0-10.50 | - |

304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.00-12.00 | - |

310 S | 0.055 | 1.5 | 0.04 | 0.005 | 0.7 | 25.0-28.0 | 19-22 | - |

314 | 0.25 | 2 | 0.045 | 0.03 | 1.50-3.00 | 23.00-26.00 | 19.00-22.00 | - |

316 | 0.06 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

316Ti | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.00-19.00 | 9.00-13.00 | - |

321 | 0.06 | 2 | 0.045 | 0.01 | .40-.60 | 17-19.00 | 9.4-9.6 | - |

ER308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17-19 | 9.5-13.0 | - |

ER308L | 0.025 | 1.50/2.00 | 0.025 | 0.02 | 0.5 | 19.0/21.0 | 9.5/11.0 | - |

ER309 | 0.08 | 1.50/2.50 | 0.02 | 0.015 | 0.5 | 23.0/25.0 | 20.0/14.0 | - |

ER309L | 0.025 | 1.50/2.50 | 0.02 | 0.015 | 0.5 | 23.0/25.0 | 12.0/14.0 | - |

ER316L | 0.02 | 1.50/2.00 | 0.02 | 0.02 | 0.5 | 18.0/20.0 | 12.00-14.00 | 2.00-3.00 |

430L | 0.03 | 1 | 0.04 | 0.03 | 1 | 16.00-18.00 | - | |

434 | 0.08 | 1 | 0.04 | 0.03 | 1 | 16.00-18.00 | - | 0.90-1.40 |

Application

Stainless steel wire is mainly used in below fields:

1) Electric power, petroleum, boiler, high or low temperature resistant, corrosion resistant.

2) Tableware, cabinet, cutting tool, boiler, auto part.

3) Medical instruments, building materials, food industry.

4) Sea, chemical industry and machine manufacture.Or they can be made upon negotiation.

Packaging Details: plastic film inside, woven bag or hessian cloth outside.

Delivery Detail: up to the quantity,usually10-15 days

.jpg)