Ditch Cover of Steel Grating(factory)

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100tons per day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Steel Grating;fence;Gabion Mesh |

Product Detail

| Model No.: | YC-SG05 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Steel Plate |

| Surface Treatment: | Galvanized |

| Technique: | Hot Rolled |

| Brand Name: | YACHAO |

| Steel Grade: | Low carbon steel, stainless steel |

| Production Capacity: | 100tons per day |

| Packing: | Pallets in containers packed by steel strap and worthy sea shipping |

| Delivery Date: | 10-20days after confirmation |

Product Description

Ditch Cover of Steel Grating

1,Material:Low carbon steel, stainless steel

2,Surface treatment:Hot-dipped galvanized,painted, untreated

Surface Process of Gratings

1)Hot-dipped galvanizing

Normally, hot-dipped galvanizing will be carried out after end welding process. When the thickness of bearing bars is not less than 5mm,the weight of average Zinc Layer will not be less than 610g/m^2.When the thickness of bearing bars is less than 5mm,the weight of average Zinc Layer will not be less than 460g/m^2.The quality and requirements after hot-dipped galvanizing are according to the standards of GB/T13912

Note: In the range of PH6 to PH12.5,a stable protective film will be formed on the zinc surface. It has good anti-corrosive property.

2)Lacquering

Gain protection layer through the ways of spraying, brushing and soaking.

3)Electro Galvanizing

4)Anti-rust Oil Coating

5)Untreated

3,Min. order(MOQ): 10 pcs

4,Supply ability:100tons per day

5,price range:700-950 per ton

6,Payment terms: L/C, TT,D/P,D/A, WESTEN UNION

7,Delivery time: 10-20days after confirmation

HS Code: 7314490000

Feature

a. High strength, light weight

b. untreated or galvanized

c. Best price and quality , Earliest delivery

d. Our own workshop for HDG

e. professional supplie

Specification 4

A variety of specifications can meet all demands of shapes, sizes, spans, load capability in different conditions.

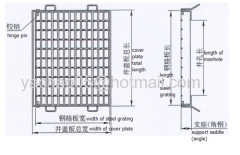

1. Drainage cover with embedded parts:

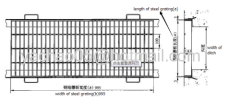

2. U-type:

As to ditches without edge, U-type Trench covers are very easy and economical.

3. Security type: steel grating hinged pit cover

Theft proof design: the cover and the frame are connected with hinges, so it's convenient for opening- up and very safe.

4. Common ditch covers:

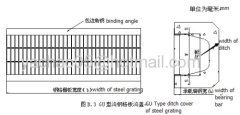

5. Installation type:

Introduction to common steel grating:

Bearing bar centers at 20mm:

This kind of fine mesh steel gratings have strong load ability and also can prevent the access of sundries of 18mm in diameter. This kind of gratings fit for pedestrian deck, walkway and ditch covers which require high security.

common welding standard: single-side full welding every 6 bearing bars.

Bearing bar centers at 30mm:

This kind of steel grating is the most commonly used in projects with American, Australian, Japan standards are available. This kind of gratings are featured well by heavy-duty, well resistance of strong impact on surface. Gratings with cross bar centers at 50mm can bear lateral impact well. This kind of steel grating fit for all kind of industrial platforms.

common welding standard: single-side full welding every 5 bearing bars.

Bearing bar centers at 40mm:

light grating and very economical. This kind of gratings fit for fixed platforms, walkway, and stair treads and British, German, French and Japanese standards are available. The products most commonly used for Belt corridor, storage shelf, Attic panel, trestle, guardrail, sunshade gate, etc.

single-side full welding every 4 bearing bars.

Bearing bar centers at 60mm:

This kind of steel gratings are especially used for mining industries. It can solve the problem that mineral splashing down and stacks on the walkway. This product usually used for mineral miningand processing and it is the best choice for workshop, meeting room and suspended ceiling of stadium in terms of it's light weight.

common welding standard: single-side full welding every 3 bearing bars.

PackagingDetails:Pallets in containers packed by steel strap and worthy sea shipping, or according to the customers' requirements

Delivery Detail: 10-20 days after confirmation

14,How to order:

1.Kindly indicate the specifications ,sizes ,quantities ,and required surface treatment of steel grating.

2.Give type and quantity of fastener .In principle ,each piece of grating needs four set of fasteners.

3.Please offer construction plan when big floor areas are required to cover with steel gratings .Also provide constructional elevation drawing and joint details as well as the section size and location of supporting steel beam ,if any openings are required on such floor areas.

4.When ordering stair treads ,please state out types of stair treads ,and the specification ,length ,width ,quantity and required surface treatment for gratings used.

5.For more information ,please contact our company's sales department .We shall du our best to help you.

Why choose us?

1. We are a company of steel grating at the same time, a professional factory, founded in 1993, price are much competitive.

2. We have fully automatic welding equipment taking the place of the original manual welding machines. The new welding technology is in advance. It can make solid, good, uniform joints.

3. We have leading domestic CAD steel grid plate designing system, which can provide users with accurate product drawings and installation drawings. Customers can get installing guiding, too.

4. The punctual delivery of goods.

5. Good after-sales service.

FAQ:

1. How can I get a exactly quotation?

There are three ways:

a. You can tell me the bearing bar size and the pitch of bearing bar and cross bar

b. You can tell me the carrying capacity of per square meter and the maximum span.

c. You can send me the drawings about steel grating

2. What are the size of steel grating common specifications?

a. The grating that the pitch between bearing bar is 30mm,is most widely used type in industrial field.

b. The grating that the pitch between bearing bar is 40mm is the most economical and lightest type. It is the best choice for you on occasions that the clear span is small

c. The grating is the pitch between bearing bar is 60mm and the pitch between cross bar is 50mm is developed specially for mining industry. It solves the problem of mineral splash on the plate.

d. The grating with the pitch of 30mm between bearing bar and of 75mm between cross bar is the most popular type used home and abroad. It is proper for many applications such as walkways , platforms ,etc.

3. What are the size of common steel grating stair tread?

The bearing bar size are 25*3mm, 25*5mm, 32*5mm

The pitch of bearing bar are 30mm and 40mm.

4. What standard can your steel grating meet?

We can produce steel grating according to different countries.

Such as China YB/T4001.1-2007,USA ANSI/NAAMM(MBG531-88),UK BS4592-1-1995 Australia AS1657-1992 and so on

5. How about your factory strength?

We have more than 100 staff , and there are 40 have 20 years of experience in this industry.

We have a complete set of production line.

6. Which countries do you export to?

We currently export to Singapore, Vietnam, Thailand, USA, Kuwait, Austria, Japan and so on.

7. The sample question

We can supply free common steel grating sample and the sample will be readly in four days.

8. The delivery problems

We usually need 10-20 days to produce 20' container (about 20tons) after confirmation.