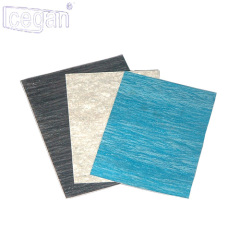

non-asbestos rubber sheet with wire

| Min. Order: | 1000 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,FAS,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 400ton per month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | XB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standard or Nonstandard: | Standard |

| Style: | Mechanical Seal |

| Material: | Rubber |

| Brand Name: | bright pearl |

| Production Capacity: | 400ton per month |

| Packing: | in roll or in wooden pallet of about 1000 kgs, 2000kgs net each |

| Delivery Date: | 15 days after received advance payment |

Product Description

Non-asbestos rubber sheet series

Non-Asbestos Jointing Sheets are made of special no-asbestos heat-resisting fiber, heat-resisting packing material, and special nature or NBR rubber compound heating and compression molding it.

Non-asbestos rubber sheet series include: NXB200, NXB300, NXB350

Uses: Used for the equipment in water, steam, etc. and used as sealing material in the joints of pipeline

Working pressure: 1.5~8.0 MPa ,Working temperature: 150 ~450℃.Oil-resistance non-asbestos rubber sheet series include: NNY150, NNY250, NNY300, NNY350.

Uses: Mainly used as the aviation liquid the motive's kerosene, lubricant, the fuel oil and cold air system to join together the seal completely of place the sealing gasket material.

Working pressure: 7.0~12 MPa, Working temperature: 150 ~450℃

Available Sizes:

Thickness: 0.5 to 5mm

1500 x 4500mm, 1500 x 4100mm, 1300 x 3850mm, 1500 x 2000mm,

1500 x 1500mm, 1500 x 1360mm, 1500 x 1000mm , 1270 x 1270mm,

The other size is optional or according to the requirements of customers.

At the same time, steel wire net inserted (coated graphite) is available.

Packing: in wooden pallet of about 1000 kgs, 2000kgs net each.

Non-Asbesto Rubber Sheet Date Sheet

GB/T3985-2008

| Item | NXB200 | NXB300 | NXB350 | NNY150 | NNY250 | NNY300 | NNY350 | |

| Tensile strength MPa≥ | 6.0 | 8.0 | 11.0 | 8.0 | 10.0 | 12.0 | 15.0 | |

| Aging Coefficient ≥ | 0.9 | |||||||

| Density g/cm³ | 1.8~1.9 | |||||||

| Compressibility % | 12 ± 7 | |||||||

| Normal temperature Pliability | Bend 180 degree on the round column (the column diameter is 12 multiple sample thickness) | |||||||

| Rebound degree | 35 | 40 | 45 | 40 | 45 | 50 | 50 | |

| Worm change Relaxation rate % ≤ | 45 | 45 | 45 | 40 | 40 | 30 | 30 | |

| Dipped in IRM903 oil with 149℃ for 5 hours | Horizontal Strain MPa≥ | ---------- | 4.0 | 6.0 | 8.0 | 9.0 | ||

| Weight increasing % ≤ | ---------- | 30 | ||||||

| Appearance change | ----------

| No air bubble | ||||||

| Dipped in ASTM fuel oil B with 21℃-30℃ for 5 hours | Thickness increasing% | ---------- | 0~20 | 5~25 | 5~20 | 5~20 | ||

| Pliability | Bend 180 degree on the round column (the column diameter is 12 multiple sample thickness), | |||||||

| Cauterization to the metal material | ---------- | No Cauterization | ||||||

| Normal temperature oil Airtightness | Medium pressure MPa | ---------- | 7.0 | 9.0 | 11 | 12 | ||

| Airtightness request | Keep for 30min, no leak | |||||||

| Nitrogen leakage rate [(ml/h.mm)] ≤ | 300 | |||||||