Disc brake pad D797

| Min. Order: | 100 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20,000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | ANYINGJIE |

| Automobile Friction: | Semi Metallic |

| Size: | Standard Size |

| Type: | Brakepads |

| Quality: | Oem Product |

| Quantity Guarrantee: | Fast delivery |

| Production Capacity: | 20,000 |

| Packing: | Carton |

| Delivery Date: | 30days |

Product Description

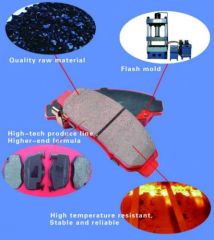

1)High quality brake pads

2) corrosion and abrasion resistant

3) with beautiful and smooth surface

4) Vehicle Specific Engineered Designs that Meet or Exceed OE Specifications

5) high precision of size

6) requires little attention

7) precoated sand shell mold precision casting, not general clay sand casting

Packaging & Delivery

| Packaging Details: | 1.Poly bag & box & carton & pallet (4pcs/set, 1set/boxes, 12 boxes/carton) 2. Card packing 3.neutral packing or with your brand 4.we also can packing as your demand |

| Delivery Detail: | 30-45 days after order confirmed |

What is the warranty

30000kms and 50000kms .

brake pads include shims or not?

According to customer's

Delivery time?

30-45 days after order confirmed

What is "Positive Molding Technology" and why is it better?

Positive Molding Technology is an important factor in production of Top products.Positive molding results in a more uniform density in the production of the brake pad. It also allows using less resin content in formulation of the brake pad which can lead to improvement in the fading characteristic of the brake pad. The brake pads produced by positive molding process is proven to have much better stopping performance.

How Can I Replace My Own Brakes

1.Get the correct brake pads.

2.Make sure the vehicle is cooled down.

3.Loosen the lug nuts.

4.Carefully jack the car up until it can be removed comfortably.

5.Remove the wheels.

6.Tighten the lug nuts.

7.Start the vehicle.

8.Test your new brake pads.