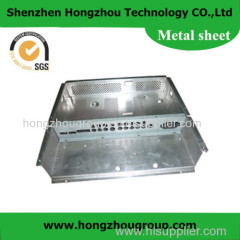

Custom Design High Quality Sheet Metal From Factory

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50000pcs per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Sheet Metal Fabrication, Heat Sink, PCB Assembly, Stamping Part, PCB |

Product Detail

| Model No.: | HZ-006 |

|---|---|

| Brand Name: | Hongzhou |

| Item: | Sheet Metal Part/Sheet Metal Fabrication |

| Processing: | Stamping/ Punching/ Bending/ Welding |

| Size: | Custom |

| Service: | OEM/ODM |

| Quality Control: | 100% Inspect Before Shipment |

| Packing Detail: | Standard Export Packing |

| Delivery Lead Time: | 7-25 Working Days(as Per Your Order Qty) |

| Factory Location: | Shenzhen, China |

| Export Markets: | Global |

| Production Capacity: | 50000pcs per month |

| Packing: | standard export packing |

| Delivery Date: | 5-12 business day,as per your order qty |

Product Description

Sheet metal fabrication/ Sheet metal parts

About us:

Shenzhen Hongzhou Group, founded in 2005, is an ISO9001: 2008 certified, vertically integrated manufacturing corporation, have powerful and high quality modular mode shopfloors from CNC machining, Aluminum extrusion(heat sink), plastic injection molding, sheet metal fabrication(laser cutting, stamping, bending, welding, polishing, assembly process), to cable and wire assembly, PCB assembly(SMP&DIP process), final assembly, as a vertically integrated corporation with manufacturing modules incorporating design, development, prototyping and tooling, production, assembly, testing, quality control, certification, customer's location's Kanban warehouse storage and logistics, we can offer customers with unit component and in-house integrated assembly and testing value-added service.

Product details:

Manufacturing Process | Laser cutting,stamping, deep stamping,bending, punching, threading,welding, polishing,tapping,riveting,assembly. |

| Material | Stainless steel, carbon steel,copper,aluminium, brass, iron, and bronze (according to customer's requirements) |

| Surface Treatment | Galvanized(zinc-plated, nickel-plated,chrome-plated,silver-plated), powder coating, polishing(mirror polishing, electrolytic polishing), brushing,sand blasting,chemical etching,passivation treatment, etc. |

| Tolerance | +/-0.01mm |

| Package | Plastic film+harden carton box+plywood case |

| Application | Auto parts,Food Machinery,medical testing and equipment, electronic products, electric appliance,power switches, miniature switches,A/V equipment. |

| Quality Control | Conducted by ISO9001 |

| Drawing File Format | Solidworks,Pro/E,,Auto CAD,PDF |

| Features | 1.Customized Design 2.Small Order Allowed 3.Sample Product Available 4.Competitive Price due to factory direct supply |

| Inspection | IQC,PQC,FQC,OQA |

Production Process

1) Production process depends on the requirements of the products and design.

2) The sheet metal fabrication is made under the process of CNC punching,Bending,

Tig/Mag welding, Die stamping, Spinning, Surface treatment, etc.

3) To ensure the high quality of the metal sheet fabrication part, the company does

precision machining & strict inspection.

Our advantages

Quick Response: your inquiry will be replied in 24 hours.

Competitive Price directly from the original manufacturer.

High quality due to first-hand control in factory.

OEM/ODM:custom fabrication according to your drawings or samples.

Flexibility:small orders are acceptable for quick delivery and help you reduce the stock

cost.

Quick delivery. We have overseas warehouse located in Hongkong and London.