Full Automtaic Wire Harness Processing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Wire Harness Processing Machine |

Product Detail

| Model No.: | NKM-600 |

|---|---|

| Means of Transport: | Ocean, Land |

| Item: | Auomatic Wire Harness Processing Machine |

| Function: | two ends automatic wire cutting,striping,tinning,crimping,shell inserting |

| Size: | 1600W*1400D*14501400H |

| Weight: | 680kg |

| Capacity: | 2700pcs/h |

| Operating wire colors: | 7 colors with the same time |

| Wire size: | UL1571#30~#24; OD under1.5mm |

| Wire cutting length: | 82-600mm |

| Wire striping length: | 1.0~6.0mm on both sides |

| Power: | Ac180~220V;50/60Hz, 3 phase, 10A |

| Production Capacity: | 100 sets per month |

| Packing: | Polywooden case |

| Delivery Date: | one month |

Product Description

Full Automtaic Wire Harness Processing Machine

Description:

Technical leader of automatic wire harness processing machine. Full automatic terminal inserting

shell machine isn't strange to us, it's developed in Japan years before, but because of it's complex

structure,high price and low universality, only five such machines was sold. Now we Nikon technology

solved the hard technological problem, and developed one end and two ends automatic terminal

inserting shell machine with much lower cost and stable performance,realizing all in one full automatic

operataion of wire cutting, two ends stripping, crimping and inserting shell

Hope we could help you save much labor cost and thus bring you huge profit.

Features:

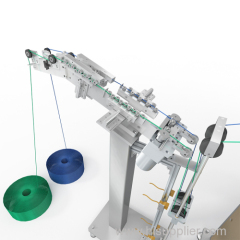

1. Handling mechanism is linear type which could load material with electric wire till the product is

excluded totally.

2. Stripping, crimping and inserting into plastic shell on both ends at the same time.

3. 2-color and 7-color selector, inserting mechanism with 2 sections, reversing and changing clamp

and then servo operate.

4. Provided with terminal pressure detector with high precision; automatically detecting by CCD visual

system.

Techinical Parameter:

| Model | NKM-600 Automatic Two Ends Terminal Shell Inserting Machine | |||||||

| Function | Wire feeding and cutting; two ends stripping,crimping and shell inserting; automatic setting of crimping and inserting position; Housing feeder; Selection and excluding of poor products; Automatic selection and alternating for 2 colors wires. | |||||||

| Capacity | 2700pcs/h | |||||||

| Operation wire size | UI1571 AWG#30-#24,outer diameter under 1.5mm | |||||||

| Wire cutting length | 82mm-600mm | |||||||

| Wire cutting precise | Deviation1.0mm+(setted cutting length*0.002) | |||||||

| Striping length | 1.0~6.0mm on both dends | |||||||

| Crimping pressure | 7.8NKM(800KG),two servo crimping devices (automatic crimping position adjustment) | |||||||

| Terminal crimping device | NKM special mini crimping device(no cutting for terminal edge). | |||||||

| Detector | Wire feeding; wire over loading;stripping error; pressure inspection; terminal feeding; terminal overlodading;HOUSING feeding; improper terminal inserting | |||||||

| Power | AC 220V/240V, 50/60HZ 3 phase, 10A | |||||||

| Compressed air | 0.6MPa, about120Nl/min(should be clean and dry) | |||||||

| Size&weight | 1600W*1400D*1400H(mm),excluding the protruding part, Weight:680Kg. | |||||||

| Other function | Terminal egde cutting device(mounted beside the terminal crimping device);Paper rolling devide with terminal vertical feeding function(2 units) | |||||||

| Potentional Part | Wire feeder( 2 colors,7 colors,10 colors optional); Selection conventor for 10 color lines;layer inspection and automatic inspection device for mounting postion of HOUSING. | |||||||

Factory Show:

Contact us:

.jpg)

.jpg)