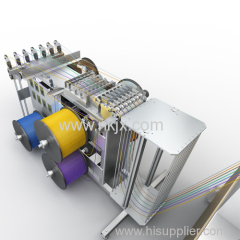

Full Automatic One End Tinning Terminal Housing Inserting Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Wire Harness Processing Machine |

Product Detail

| Model No.: | NKM-07 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Item: | Full Automatic One End Tinning Terminal Housing Inserting Machine |

| Function: | Full automatic wire cutting,striping,tinning,crimping,connector inserting |

| Size: | 1400W*900D*1450H |

| Weight: | 900kg |

| Capacity: | 2700pcs/h |

| Operating wire colors: | 7 colors with the same time |

| Wire size: | UL1.368#30~#26;UL1.368#22~#28 |

| Wire cutting length: | 35-1200mm |

| Wire striping length: | Tinning end:1~10mm; Terminal crimping end: 1.0~3.0mm |

| Power: | Ac180~220V;50/60Hz, 3 phase, 10A |

| Production Capacity: | 100 sets per month |

| Packing: | Polywooden case |

| Delivery Date: | one month |

Product Description

NKM-07 Full Automatic One End Terminal Connector Inserting Machine

Description:

Technical leader of automatic wire harness processing machine. Full automatic terminal connector inserting machine isn't strange to us, it's developed in Japan years before,

but because of it's complex structure,high price and low universality, only five such

machines was sold. Now we Nikon technology solved the hard technological problem,

and developed one end and two ends automatic terminal inserting shell machine with

much lower cost and stable performance. Hope we could help you save much labor cost

and thus bring you huge profit.

Features:

1. There are 7 sets feeding devices inside host which are automatic single-end tinning terminal connector inserting machine with 7 lines.

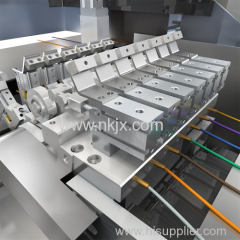

2. The machine has a terminal tension-compression dynamometer with high accuracy and CCD

vision inspection to detect wire harness, thus it does not need manual detection.

3. Combined processing based on the electric wires with different colors and different cutting lengths

4. It could be used as single-end tinning machine when the function of inserting plastic shell is not used

5. Locating and inserting accurately according to the hole's type of plastic shell.

Techinical Parameters:

| Model | NKM-07 Full Automatic One Ends Terminal Connector Inserting Machine | |||||||

| Function | Wire cutting, one end tinning(twist and tin), one end crimping and shelling inserting,automatic setting of cutting length and crimping posintion. | |||||||

| Capacity | 2700pcs/h | |||||||

| Operation wire size | UI10368#30-#26 or Ul1.368#22-#28, outer diameter under 1.6mm | |||||||

| Wire color | 7 colors(with same size) | |||||||

| Wire cutting length | 35mm-1200mm | |||||||

| Wire cutting precise | Deviation1.0mm+(setted cutting length*0.002) | |||||||

| Striping length | Tinning end: 1-10mm; Crimping end: 1.0-3.0mm | |||||||

| Crimping pressure | 14700N(1.5ton),one servo crimping device( automatic crimping position adjustment) | |||||||

| Holder size | Within 40W*16D*14H(mm) | |||||||

| Detector | Wire feeding; wire over loading;stripping error; pressure inspection; terminal feeding; terminal overlodading; Improper terminal crimping & inserting | |||||||

| Power | AC 180~220V, 50/60HZ 3 phase, 10A | |||||||

| Compressed air | 0.6MPa, about120Nl/min(should be clean and dry) | |||||||

| Size&weight | 1400W*900D*1450H(mm),excluding the protruding part, Weight:900Kg. | |||||||

| Other function | Paper rolling device with vertical terminal feeding function; wire feeder for 7 lines. | |||||||

| Potentional Part | Wire shelf( WRS20DR); Warning light; Solder wire feeder, Solder paster feeder. | |||||||

Factory Show:

Contact us: