Forged from deep hardening steel and heart treated for internal strength to

resist bell mounting and to increase rebuild ability.

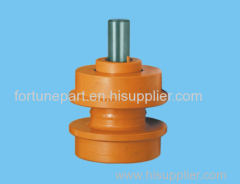

2 pieces roller shell

rim. Heat treated shells for body strength and longer wear life.

Heat treated

for a deep uniform hardened depth that providers wear life equal to link wear

life.

Thru-hardened flanges to resist bending and improve rebuild

ability

Roller Shafts

Shafts and bearing designed to carry and turn with

heavy track weight forged and heat treated for strength.

Bearing surfaces are

hardened and polished to reduce friction and wear.

Center flange absorbs side

thrust from roller shell.

Cast Iron Bushing

Supports the bronze sleeve

bearing.

Cast from iron to absorb loads without permanent

deformation.

Large lubricant reservoir reduce heat build up.

Bronzed

sleeve bearing

Sleeve design provides a large surface area for better load

distribution.

Inner diameter surface is polished to a smooth finish.

Soft

bronze coating in the bearing absorbs any small foreign particles before they

can damage the shaft and seals.

Functions:

Support the track as its most

between the sprocket and idler.

Guide the track between the sprocket and

idler.

Strength to resist failure before tread wear life is

utilized.

Treads wear life matched to track links.

Treads and flanges

rebuild able on forged shells.