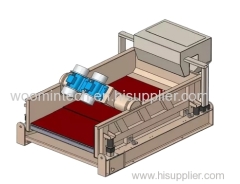

Shale Shaker of Mud Treatment System

| Trade Term: | FOB,CIF |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | korea |

Company Profile

| Location: | South Korea |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | WMSS200 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Oil |

| Type: | Drilling Rig |

| Brand Name: | WM |

Product Description

1. Shale Shaker

Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling.

They are considered to be the first phase of a solids control system on a drilling rig, they are used to remove large solids also called cuttings from the drilling fluid, more commonly called "Mud" due to its similar appearance.

Drilling fluids are integral to the drilling process and, among other functions, serve to lubricate and cool the drill bit as well as convey the drilled cuttings away from the bore hole. These fluids are a mixture of various chemicals in a water or oil based solution and can be very expensive to make.

For both environmental reasons and to reduce the cost of drilling operations, drilling fluid losses are minimized by stripping them away from the drilled cuttings before the cuttings are disposed of.

This is done using a multitude of specialized machines and tanks.

Shale shakers are the primary solids separation tool on a rig. After returning to the surface of the well the used drilling fluid flows directly to the shale shakers where it begins to be processed. Once processed by the shale shakers the drilling fluid is deposited into the mud tanks where other solid control equipment begin to remove the finer solids from it.

The solids removed by the shale shaker are discharged out of the discharge port into a separate holding tank where they await further treatment or disposal.

Shale shakers are considered by most of the drilling industry to be the most important device in the solid control system as the performance of the successive equipment directly relates to the cleanliness of the treated drilling fluid.

| Drive Principle | Utilize the screen vibrator CAM mechanisms by using the vibration motor and hydro motor |

| Drive Effect | Filter out the rock pieces involved mud, Gathering the passed mud at sand trap tank |

| Caution | Select the proper mash size with consideration for the expected cutting size and solid size |

| Additional Information | Can be reduce the mesh blocking by installing the cleaning device at the machine bottom |

| Component | Excitation Motor, Plate, Dip Adjustment Device etc. |

Specification table of Shale Shaker (Woomin technology)

| Model | WMSS200 | WMSS400 | WMSS528 | WMSS615 |

| Deck No. | Single Deck | |||

| Vibrating Mode | Linear Motion | |||

| Treating Capacity | 200GMP (45m³/h) | 400GMP (90m³/h) | 528GMP (120m³/h) | 615GMP (140m³/h) |

| Motor Power | 2 X 0.75Kw | 2 X 1.5Kw | 2 X 1.72Kw | 2 X 0.75Kw |

| Vibrating Strength | u2264 7.5G(Adjustable) | |||

| Deck Adjustment | -2° | -1 ~ 2° | -1 ~ 5° | -1 ~ 5° |

| Power | 380V / 50Hz, 460V / 60Hz or Customized | |||

| Shaker Screen | 2 Panel 1.4m² | 2 Panel 2.1m² | 3 Panel 2.6m² | 3 Panel 3.2m² |

| Dimension (Top Buffer Box) | 1650 X 1260 X 1077mm | 1975 X 1884 X 1448mm | 2403 X 1884 X 1448mm | 1830 X 1884 X 1448mm |

| Dimension (Back Buffer Box) | N/A | 2283 X 1884 X 1340 mm | 2750 X 1884 X 1340mm | 3180 X 1884 X 1340mm |

| Weight | 750kg | 1200kg | 1390kg | 1650kg |

| Remark | Capacity test at condition : Mud Weight 1.2/cm² viscosity 45s API 40 | |||

Equipment Series of Mud Treatment System