YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000 |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | YG20 carbide die |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | tungsten carbide |

| Surface: | Blank and finished |

| Grade: | YG8 YG11 YG15 YG20 |

| Certification: | ISO9001:2000 Certificate |

| Dimensions: | As per customers' requirement |

| Chemical Position: | WC+Co |

| Properties: | High hardness,excellent wear resistance |

| Sample: | Available |

| Trail Order: | Acceptable |

| Colour: | Original |

| Production Capacity: | 1000000 |

| Packing: | wooden carton |

| Delivery Date: | 10-15 days |

Product Description

YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT

Product Name:YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT

Item no:YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT

Product Description

Product Name | YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT |

Color | Original |

OEM | Yes |

Material | Cemented Carbide Tungsten |

Sample | Available |

Weight | Different weight available |

Size | Standard or Non-standard |

Length | Flexible |

Usage | Used for making dies etc |

Shape | Flexible |

Features and Benefits

1) With extreme hardness, higher thermal conductivity,stronger elastic modulus and TRS.

2) Smaller effects on hardness with the temperature.

3) Hot-crack resistance, high corrosion resistance and wear-resistance

We manufacture carbide cold forging dies for many kinds of applications, such as for metal powder and nonmetal poeder, for steel tubes and rods, for wear resistant or impact resistant application, for stainless bolt header dies and rollers, etc.

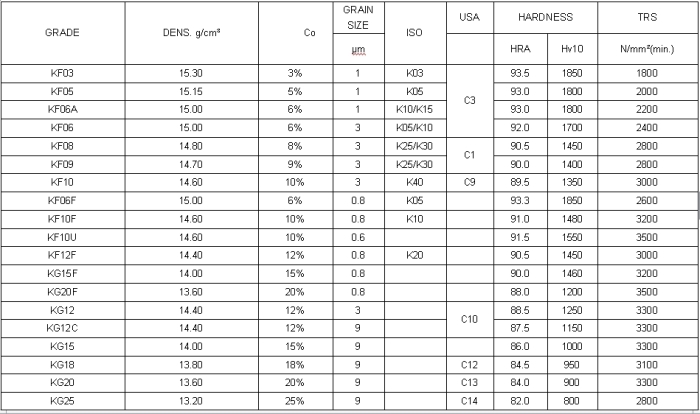

Grade: YG11, YG15, YG20, YG16C, YG20C, YG22C, YG25C,

YG20 Tungsten Carbide COLD HEADING DIE Carbide Mold For NUT BOLT

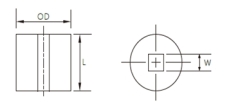

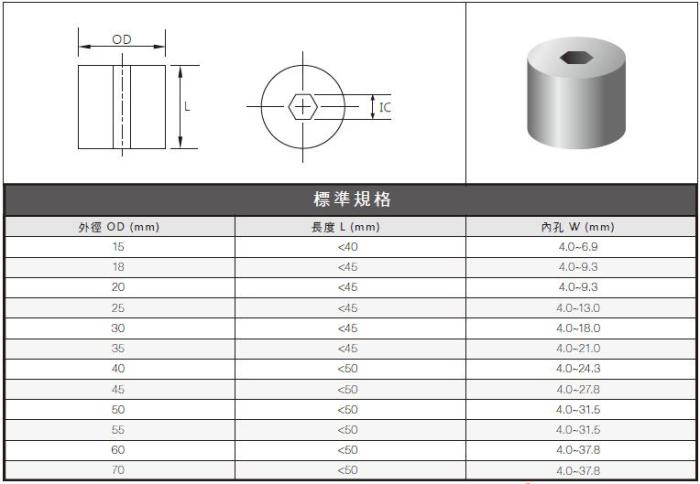

Specifications

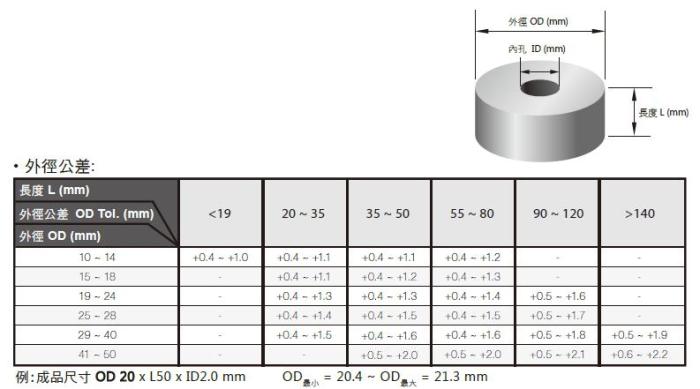

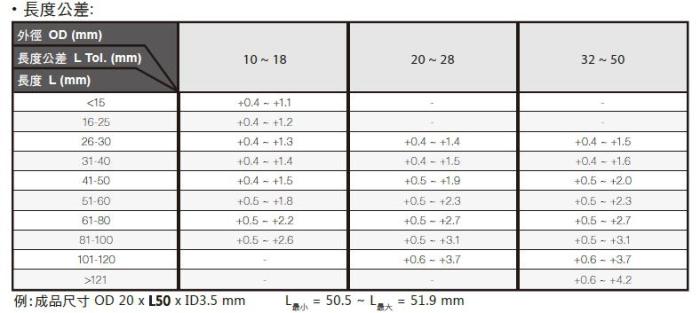

Tolerance Tables

1)Outside diameters tolerance table

2)Inside diameters tolerance table

3)Length tolerance table

Application

Making various dies

Grade chart

Production process

STEP 1:Power Mixing (No Chemical Additive,vacuum blending)

STEP 2:Put mixture powder into graphite sintered die

STEP 3:Vacuum Sintering

STEP 4:Fine finishing(universal cutter grinder,cylin-drical grinder,surface grinder)

STEP 5:Quality test(hardness tester,mearsureing projector,density meter,two dimensions measuring instrument)

About us

TaiMei Carbide New Material Technology Co., Ltd is mainly engaged in the R & D, manufacturing, and selling of cemented carbide, ultrahard materials, cermet, magnetic materials and new powder metallurgy materials, especially large-sizedcementedcarbide products. The main products cover all kinds of high end molds, key auto parts, metallurgical rollers, drawing dies, anti-wear parts in petroleum industry, sleeves, gears, anvils, cylinder pressure in machinery, wear plates, rings, excavation tools, drills in construction industry, and antiwear and pressure-proof parts in military industry, etc.

Company

Factory

Main products

Testing and inspection equipments

Sample availability and policy

We offer samples on your account,the charge can be returned when your order reach a target volumn.

Certification

Patents

Packaging & Shipping

♦ Dedicated Logistics Packaging

♦ Professional placement

♦ Professional standard laying

♦ Express delivery