Direct manufacturer ceramic vitrified bond diamond and CBN grinding wheel for surface grinding

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000 |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | diamond and CBN wheel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | CBN & diamond |

| Surface: | Blank |

| Certification: | ISO9001:2000 Certificate |

| Dimensions: | As per customers' requirement |

| Type: | Diamond/CBN |

| Properties: | High hardness,excellent wear resistance |

| Sample: | Available |

| Trail Order: | Acceptable |

| Colour: | Original |

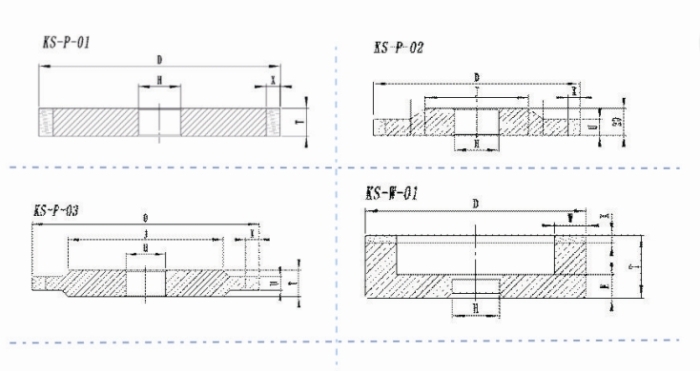

| Shape: | Disc |

| Production Capacity: | 100000 |

| Packing: | wooden carton |

| Delivery Date: | 10-15 days |

Product Description

Direct manufacturer ceramic vitrified bond diamond and CBN grinding wheel for surface grinding

Product Name:Direct manufacturer ceramic vitrified bond diamond and CBN grinding wheel for surface grinding

Item no:Direct manufacturer ceramic vitrified bond diamond and CBN grinding wheel for surface grinding

Application:

1. For cutting soft & hard wood, laminate and plywood

2. Used on push saw, reciprocating saw and table saw

Features and Benefits

1.More sharp and efficient with a unique formula and longer service life.

2.High hardness faying surface and strong homogeneity, with evenly working layers which are not easy to deformation

3.Offer more choices of better products to customers in different industries with our new model of working layers structure.

Direct manufacturer ceramic vitrified bond diamond and CBN grinding wheel for surface grinding

Specifications

Technological advantage

1) Advanced equipment.

The unique system of large automatic self-heating vacuum hot-pressing sintering (HPS) which we initiated,is not only easy to operate and simple in molding technique,but also has an obvious advantage of high efficiency and precision.

2) Advanced composite die

We took the lead in introducing high strength composite die in manufacturing cemented carbide products,which improved the product quality greatly.

3) Technical maturity

Exclusive technology of charging and vacuum blending,ensures the product purity and no harmful gas casued.

4) Unique technique

Our new technique has excellent performance of high efficiency, energy saving and environmental protection,

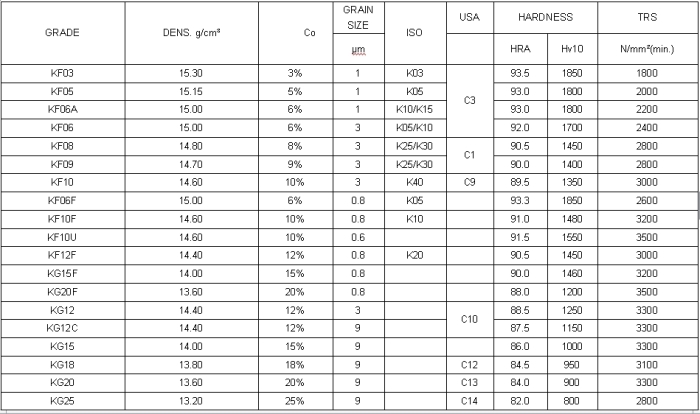

Grade chart

Production process

STEP 1:Power Mixing (No Chemical Additive,vacuum blending)

STEP 2:Put mixture powder into graphite sintered die

STEP 3:Vacuum Sintering

STEP 4:Fine finishing(universal cutter grinder,cylin-drical grinder,surface grinder)

STEP 5:Quality test(hardness tester,mearsureing projector,density meter,two dimensions measuring instrument)

About us

TaiMei Carbide New Material Technology Co., Ltd is mainly engaged in the R & D, manufacturing, and selling of cemented carbide, ultrahard materials, cermet, magnetic materials and new powder metallurgy materials, especially large-sizedcementedcarbide products. The main products cover all kinds of high end molds, key auto parts, metallurgical rollers, drawing dies, anti-wear parts in petroleum industry, sleeves, gears, anvils, cylinder pressure in machinery, wear plates, rings, excavation tools, drills in construction industry, and antiwear and pressure-proof parts in military industry, etc.

Company

Factory

Main products

Testing and inspection equipments

Sample availability and policy

We offer samples on your account,the charge can be returned when your order reach a target volumn.

Certification

Patents

Packaging & Shipping

♦ Dedicated Logistics Packaging

♦ Professional placement

♦ Professional standard laying

♦ Express delivery