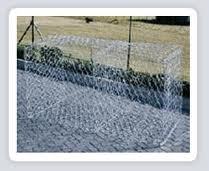

gabion mesh / gabion box

| Min. Order: | 10 Square Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000 square meter |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Fencing Metal Mesh, Barbed Wire, Gabion Box, Chain Linkl Fence, Welded Wire Mesh |

Product Detail

| Model No.: | YC-GM01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| factory: | Anping |

| company: | manufacture |

| contact: | Ms Lynn |

| Mobile: | 15620908717 |

| skype: | yachao06@hotmail.com |

| email: | yachao06@hotmail.com |

| Production Capacity: | 10000 square meter |

| Packing: | as request |

| Delivery Date: | 10days-20 days after confirmed |

Product Description

hot-dipped galvanized gabion box

Material:high quality low carbon steel wire, stainless steel wire , PVC coated wire , Iron wire ,etc

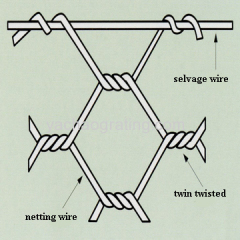

Weaving patters:Straight twist, reverse twist, double twist.

Suface treatmeat

Electro galv. hexagonal wire netting :galv. after weaving

Electro galv. hexagonal wire netting : galv. before weaving

Hot dipped galv. hexagonal wire netting : galv. after weaving

Hot dipped galv. hexagonal wire netting : galv. before weaving

Stainless steel hexagonal wire netting

Application:

A. Control and guide of water or flood

B. Preventing of rock breaking

C. Water and soil protection

D. Protection engineering of seaside area

Model | Hole (mm) | Mesh wire(mm) | Side wire(mm) | Binding wire(mm) | Max width |

DL60 | 60X80 | 2.0~2.8 | 3.0~4.0 | 2.0~2.2 | 4M |

DL180 | 80X100 | 2.0~3.0 | 3.0~4.0 | 2.0~2.2 | 4M |

DL80W | 80X120 | 2.0~3.0 | 3.0~4.0 | 2.0~2.2 | 4M |

DL100W | 100X120 | 2.0~3.0 | 3.0~4.0 | 2.0~2.2 | 4M |

DL100W | 100X150 | 2.0~3.0 | 3.0~4.0 | 2.0~2.2 | 4M |

DL120 | 120X150 | 2.0~3.0 | 3.0~4.0 | 2.0~2.2 | 4M |

Length (m) | Width (m) | Height (m) | Spacer number | Volume (m2) | Tolerance range |

2.0 | 1.0 | 0.15---0.3 | 1 | 0.3~0.6 |

Length :±/-3% Width :±/-5% Height :±/-5% |

3.0 | 1.0 | 0.15---0.3 | 2 | 0.45~0.9 | |

4.0 | 1.0 | 0.15---0.3 | 3 | 0.6~1.2 | |

2.0 | 1.0 | 0.5 | 1 | 1.0 | |

3.0 | 1.0 | 0.5 | 2 | 1.5 | |

4.0 | 1.0 | 0.5 | 3 | 2.0 | |

1.0 | 1.0 | 1.0 | 0 | 1.0 | |

1.5 | 1.0 | 1.0 | 0 | 1.5 | |

2.0 | 1.0 | 1.0 | 1 | 2.0 | |

3.0 | 1.0 | 1.0 | 2 | 3.0 | |

4.0 | 1.0 | 1.0 | 3 | 4.0 |

How to install welded gabion mesh?

Step 1. Ends, diaphragms, front and back panels are placed upright on the bottom section of wire mesh.

Step 2. Secure panels by screwing spiral binders through the mesh openings in adjacent panels.

Step 3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing, and crimped over the line and cross wires on the front and side faces. None are needed in interior cells.

Step 4. Gabion box is filled with graded stone by hand or with a shovel.

Step 5. After filling, close the lid and secure with spiral binders at the diaphragms, ends, front and back.

Step 6. When stacking tiers of the welded gabion mesh, the lid of the lower tier may serve as the base of the upper tier. Secure with spiral binders and add pre-formed stiffeners to exterior cells before filling with graded stones.