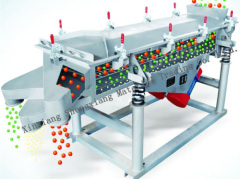

Air-cooled linear vibrating screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets in one month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DH-530 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

| Type: | Separator |

| Brand Name: | Dahan |

| power: | 1.1kw |

| capacity: | 0.08-8t/h |

| desks: | 1-5 |

| Production Capacity: | 100 sets in one month |

| Packing: | Free fumigation wooden cases |

| Delivery Date: | 7-10 days after receiving your deposite |

Product Description

work principle

Air-cooled linear vibrating screen is "Dahan brand" DZSF series linear vibrating screen, based on the inlet or bottom side of the lower end of the housing increases the cooling fan cooling system, the installation of the inlet screen and small nesting ports for the agglomeration of particulate material discharged from the large-small discharge mouth, the device can block large particles, and the impact on the buffer material of the screen, to extend the service life of the screen (for the part of the material of the device does not need be removed). Material when entering the device, located at the inlet side of the box under the bottom or side of the fan cooling system to cool its cooling operation, two vibration motors screen surface with a relatively inclination, at a reasonable role in the exciting force and material self-gravity, after cooling the material being thrown at the screen surface, leaping forward linear motion, filtered on different specifications sieve material and sieve material through the multi-screen, the layers were discharged from the discharge port, to screening and the purpose of classification.

Application

Dahan mechanical air-cooled linear vibrating screen which high temperature properties of materials design and development, can effectively reduce the temperature of the material before the material for screening, effectively improve the screening efficiency and capacity, air-cooled below an example with detergent vibrating screen applications. Immediately after completion of the production of washing powder, usually about 120 degrees of heat, if not for cooling treatment, screening classification is very difficult, and the laundry is not suitable for conventional water-cooled cooling. In washing powder production line with the "Han" brand air-cooled linear vibrating screen, just to complete the 120-degree heat produced by the transportation equipment detergent directly into the air-cooled linear vibrating screen, after installation of the device in the inlet at the bottom of the fan cooling cooling system , (caking material does not meet the requirements by installing the inlet end of the screening of the small screen next to the discharge port of discharge from the discharge port, as shown below, the device can be optional according to the material properties), can be directly Laundry powder temperature dropped to 40-50 degrees and then into linear vibrating screen to complete the screening grading work.

The main technical parameters

| Model | DZSF-520 | DZSF-525 | DZSF-816 | DZSF-1020 | DZSF-1025 | DZSF-1030 |

| Nominal(mm) | 500*2000 | 500*2500 | 800*1600 | 1000*2000 | 1000*2500 | 1000*3000 |

| Material particle size(mm) | 0.074-10 | 0.074-10 | 0.074-10 | 0.074-10 | 0.074-10 | 0.074*10 |

| Vibration time(numbers/min) | 960 | 960 | 960 | 960 | 960 | 960 |

| Screen surface inclination | 0°-7° | 0°-7° | 0°-7° | 0°-7° | 0°-7° | 0°-7° |

| The amplitude | 3-4.5 | 3-4.5 | 3-4.5 | 3-4.5 | 3-4.5 | 3-4.5 |

| Layer | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 |

| Power(KW) | 2*(0.4-0.75) | 2*(0.4-0.75) | 2*(0.4-0.75) | 2*(0.4-1.1) | 2*(0.4-1.1) | 2*(0.4-1.5) |

Installation

The device should be fixed on a dedicated foundation, by embedded bolts. If you do not play special foundations, should be between the table and the equipment base laying anti-vibration rubber sheet before using the device must be configured to secure the grounding line of protection.

Note: After installing the device in place, before starting the transport must be used to secure the base of the sieve and the device removed.

If you are interested in our products,you can contact me .