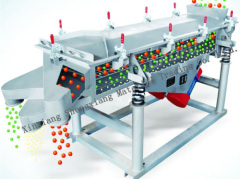

Adjustable linear vibrating screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets in one month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DH-0815 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

| Type: | Separator |

| Brand Name: | Dahan |

| power: | 1.1kw |

| capacity: | 0.1-20t/h |

| desks: | 1-6 |

| Production Capacity: | 100 sets in one month |

| Packing: | Free fumigation wooden cases |

| Delivery Date: | 7-10 days after receiving your deposite |

Product Description

Adjustable linear vibrating screen

Adjustable linear vibration screen for DZSF-0815 type, customers can adjust the angle of linear vibrating screen according to the material screening process. The machine contact parts are 304 stainless steel materials, stainless steel grid structure design, equipped with a feed hopper, adjust the feed hopper flapper can control the feed rate.Work characteristics Adjustable high linear vibrating screen product screening accuracy, large capacity, simple structure, low energy consumption, low noise, screen long life, good sealing, no dust, easy maintenance, can be used for assembly line production automation. Mainly applicable industry The product is widely used in screening chemicals, food, plastics, pharmaceuticals, metallurgy, glass, building materials, food, fertilizers, abrasives, ceramics and other industries in the dry powdered materials.

The screening machine is mainly composed of screen box, screen frame, screen, into the hopper, vibrating motor, motor pedestal, damping springs, brackets and other components.

1, Screen box: the number of different thickness steel plates welded together, with a certain strength and stiffness, is a major component of the screening machine.

2, Screen frame: a small wood made of pine or the amount of deformation is mainly used to keep the screen flat, reaching the normal screening.

3, Screen mesh: low carbon steel, brass, bronze, stainless steel wire mesh and several kinds.

4, Feeding hopper: First of all materials put into the hopper, adjust the feed hopper flapper control the feed rate, feeding evenly.

5, Vibration motor (use and maintenance methods are detailed in vibration motor manual).

6, Motor dynamo: Install vibration motor, connecting screws must be tightened before use, especially three days before the new trial screening machine, must repeatedly tightened to avoid loose causing the accident.

7, Damping spring: to prevent vibration transmitted to the ground, while supporting the full weight of the sieve box, during installation, the spring must be perpendicular to the ground.

8, stents: the four pillars and two channel composition, supports screen box, when you install the pillars must be perpendicular to the ground, the two pillars of the following channels should be parallel to each other.Screening principles Adjustable linear shaker material into the screening machine from the inlet into the hopper evenly into the silo flapper adjust the feed rate can be controlled, in the vibration motor excitation, the direction of the discharge port side to side beating sieve divided by the number of multi-mesh sieve and substandard products sieve, sieve material were discharged from their exports, inflow silo or filled barrel. Adjustable linear

Model Description

D---------------------------------Motor(vibration source)

Z---------------------------------Straight line(Running track)

SF----------------------------------------Sieve

0815--------------------Sieve size (800mm wide x1500mm long)

1 ---------------------------------One layer (one layer mesh two spout)S ---------------------------------Steel material(304 stainlesssteel material)

If you are interested in our products,you can contact me.